Top Suppliers China Ci Type High Speed 6 Color BOPP Film Flexographic Flexo Printing Machine Price

We try for excellence, service the customers”, hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Top Suppliers China Ci Type High Speed 6 Color BOPP Film Flexographic Flexo Printing Machine Price, Adhering on the small business philosophy of ‘customer 1st, forge ahead’, we sincerely welcome clientele from at your house and overseas to cooperate with us.

We try for excellence, service the customers”, hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for China Ci Flexo Press, Ci Printing Press, We have been seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

Characteristic

- The machine introduction & absorption of European technology / process manufacturing, supporting / full functional.

- After mounting the plate and registration, no longer need registration, improve yield.

- Replacing 1 set of Plate Roller (unloaded old roller, installed six new roller after tightening), only 20 Minute registration can be done by printing.

- The machine first mount plate, pre-trapping function, to be completed in advance prepress trapping in the shortest possible time.

- Maximum production machine speed up 200m/min, registration accuracy ±0.10mm.

- The overlay accuracy does not change during lifting running speed up or down.

- When machine stop, Tension can be maintained, the substrate is not deviation shift.

- The whole production line from the reel to put the finished product to achieve non-stop continuous production, maximize product yield.

- With precision structural, easy operation, easy maintenance, high degree of automation and so on, only one person can operate.

technical specifications

| Model | CHCI-E (Customizable to fit production and market requirements) | ||

| Max. Web Width | 650mm | 850mm | 1050mm |

| Max. Printing Width | 550mm | 750mm | 950mm |

| Max. Machine Speed | 300m/min | ||

| Printing Speed | 250m/min | ||

| Max. Unwind/Rewind Dia. | φ800mm | ||

| Drive Type | Gear drive | ||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | ||

| Ink | Water base ink or solvent ink | ||

| Printing length (repeat) | 400mm-900mm | ||

| Range Of Substrates | Film,PAPER,NONWOVEN, ALUMINUM FOIL | ||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | ||

Unwinder unit

- Single unwind central drive , with servo motor ,Inverter control Closed-loop.

- Tension control : Adopt Light float roller . tension auto compensation ,close-loop control.

- Air shaft loading material.

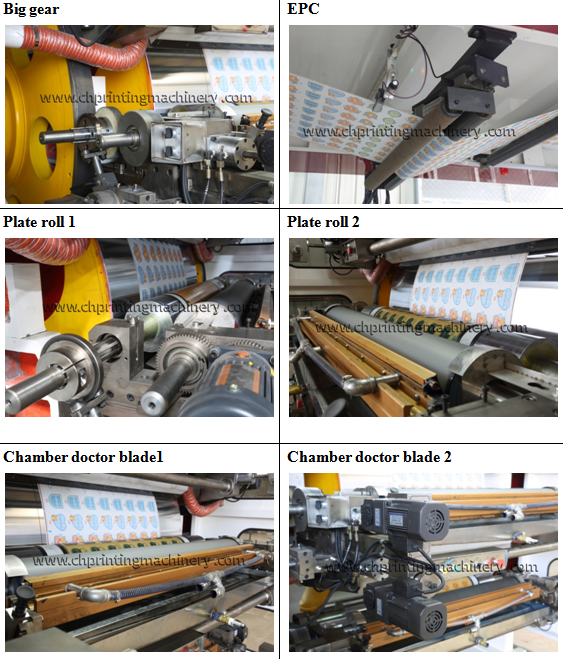

- EPC (edge position control): Set and run four roll type automatically EPC ultrasonic detector system; With manually/automatically/ central return function, can adjust left and right around ±65mm width.

Printing Unit

- Number of printing decks: 4/6/8

- Drive mode: Gear Drive

- Drive motor : Servo Motor drive ; Inverter control close loop control

- Printing way : 1)Plate -Photopolymer plate ; 2)Ink–water base or solvent ink

- Printing Repeat: 400-900mm

- Gearing of printing cylinder: 5mm

Doctor blade

- Chamber blade 4/6/8 pcs

- Both way blade aluminium alloy ink box.

- Closed ink tank(original import use life 30-60days).

- Blade open and close by manual (Safety).

- Equipped with doctor chamber for fast change.

- It is made from Aluminum alloy and closed type to reduce solvent volatilization and keep the ink in good viscosity and clean.

- There is forward and reverse directions doctor inside the chamber. The reverse doctor is for sealing the chamber and the forward doctor is for scratching the ink.

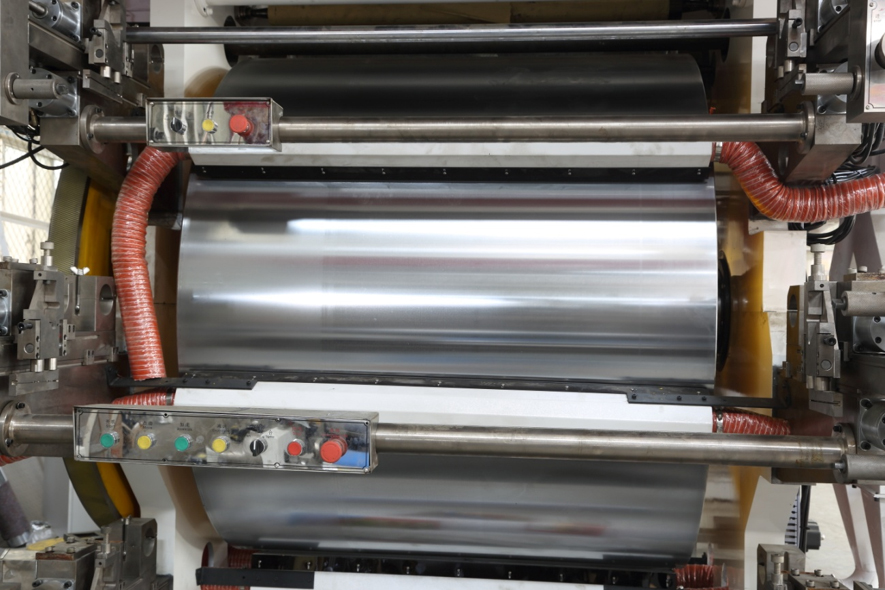

Big Central Drum

- Surface of central press roller with constant temperature.

- ±0.008mm

- Accuracy control: within ±1℃

- Diameter: Ф 1200mm/1600mm

- Made in China

- The central drum adopt hollow with two layers structure, made from superior alloy steel and precise dynamic balance treatment and surface electroplated treatment to make the frame surface without etching.

- The central impressing drum adopts high precise imported double row roller.

Dryer between each color

- Electrical heating, transformed into circulating air heating by heat exchanger. Temperature control adopts intelligent temperature control, contactless solid-state relay, set 2 control, suit to different technology、environment production, save energy consumption, enforce PID temperature control and temperature control precision,±2℃.

- Dry box between each color has windleitung and return wind pipe.

- Stainless steel cover, aluminium alloy spray nozzle.

Drying system

- Hot air mode:Electrical heating, transformed into circulating air heating by heat exchanger. Temperature control adopts intelligent temperature control, contactless solid-state relay, set 2 control, suit to different technology、environment production, save energy consumption, enforce PID temperature control and temperature control precision,±2℃.

Drying oven structure

- Drying oven inner container.

- Heat exchanger.

- Muzzle are all made of stainless steel plate.

- Dry oven has independent fan for intake air and independent fan for air exhaust. By control the supply air rate and adjust air damper, the machine printing process will get the best wind speed、wind pressure, higher drying oven heat efficiency, and save energy consumption; Cylinder control the drying oven opening and closing, with guard bar and walkway floor.

Single rewind

- One unit use center drive rewind,servo motor ,Inverter closed-loop control.

- Tension control: adopt super light float roller, and tension automatic compensation, closed-loop control.

- Automatic stop machine when break the material; When machine stop, keep tension and avoid the material loose or line deflection.

- Air shaft loading

- Inspection light

Image static monitoring system

- Display resolution: 1280*1024

- Enlargement factor: 3-30(Enlargement factor of area)

- Display mode: Full screen

- Image capture interval: decided by PG encoder/ gear sensor position signal.

- Camera check speed: 1.0m/min

- Check range: depends on the material width, arbitrarily setting. It is ok for adjustable point monitor or automatic back and forth.

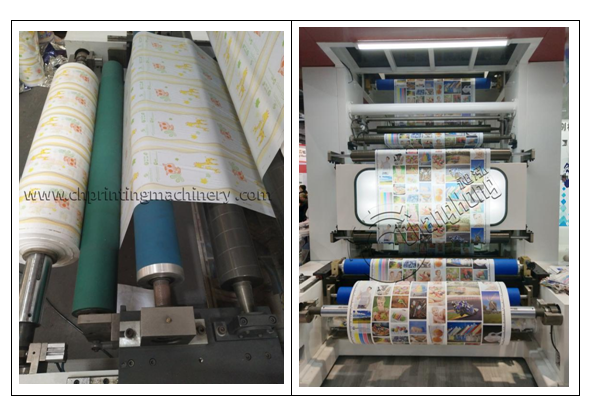

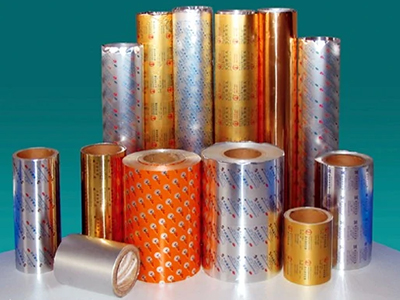

Printing Samples

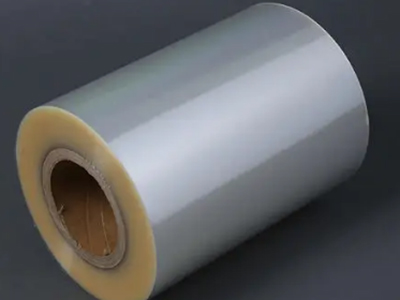

Main processed materials

Paper

Film

Non woven

Aluminum Foil

We try for excellence, service the customers”, hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Top Suppliers China Ci Type High Speed 6 Color BOPP Film Flexographic Flexo Printing Machine Price, Adhering on the small business philosophy of ‘customer 1st, forge ahead’, we sincerely welcome clientele from at your house and overseas to cooperate with us.

Top Suppliers China Ci Flexo Press, Ci Printing Press, We have been seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.