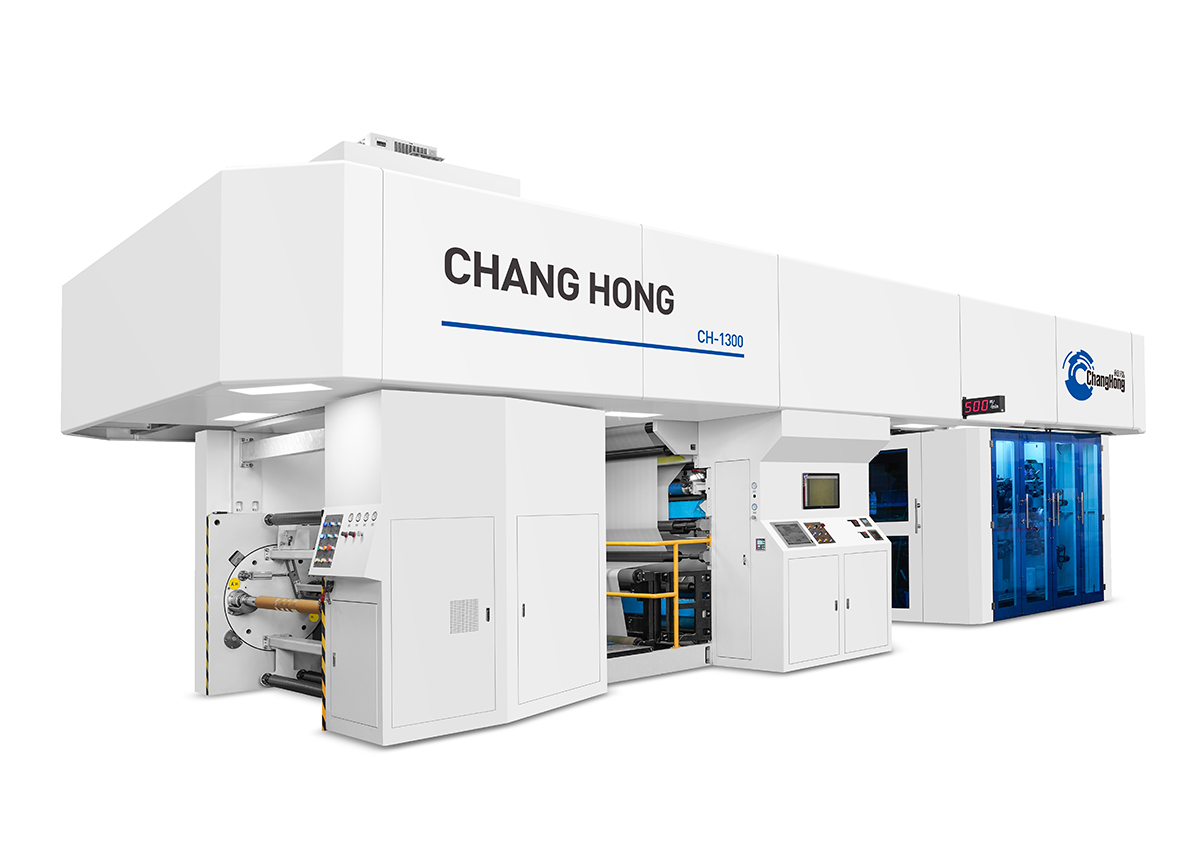

Top Grade 2025 New Style High-Speed 6 Color Flexo Printing Machinery for Plastic Film

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Top Grade 2025 New Style High-Speed 6 Color Flexo Printing Machinery for Plastic Film, We are going to wholeheartedly welcome all clientele while in the industry both of those in your house and overseas to cooperate hand in hand, and create a dazzling long run jointly.

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Flexo Printing Machinery and High-Speed Printing Machinery, We’re looking forward to establishing a mutually beneficial relationship with you based on our high-quality products and solutions, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

technical specifications

| Model | CH4-600P | CH4-800P | CH4-1000P | CH4-1200P |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 120m/min | |||

| Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Timing belt drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-1000mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High Precision Printing: equipped with advanced technology and high-quality components, which help in achieving accurate and vibrant printing on woven bags.

2. Variable printing speed: The printing speed of the machine can be adjusted according to the printing requirements, which offers greater flexibility during the printing process.

3. High production capacity: PP woven bag flexo printing machines have a high production capacity, enabling the printing of large quantities of woven bags in a shorter time span.

4.Low wastage: The PP woven bag Stack flexo printing machine consumes less ink and produces less wastage.

5.Environmentally friendly: PP woven bag stack flexo printing machines use water-based inks and produce minimal waste, making them eco-friendly.

Details Dispaly

sample

Packaging and Delivery

FAQ

Q:What are the features of a PP woven bag stack flexo printing machine?

A:The features of a PP woven bag stack flexo printing machine typically include an advanced PLC control system, servo motor control, automatic tension control, automatic register system, and more. These features ensure high precision and quality printing.

Q: How does a PP woven bag stack flexo printing machine print on bags?

A:A PP woven bag stack flexo printing machine uses specialized ink and a printing plate to transfer the desired image or text onto the PP woven bags. The bags are loaded onto the machine and fed through rollers to ensure the ink is evenly applied.

Q: What maintenance is required for a PP woven bag stack flexo printing machine?

A:Maintenance requirements for a PP woven bag stack flexo printing machine typically include regular cleaning and lubrication of moving parts, as well as periodic replacement of wear and tear components, such as printing plates and ink rollers.

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living forTop Grade 2025 New Style High-Speed 6 Color Flexo Printing Machinery for Plastic Film, We are going to wholeheartedly welcome all clientele while in the industry both of those in your house and overseas to cooperate hand in hand, and create a dazzling long run jointly.

Top Grade Flexo Printing Machinery and High-Speed Printing Machinery, We’re looking forward to establishing a mutually beneficial relationship with you based on our high-quality products and solutions, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.