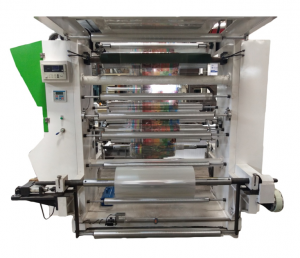

Special Price for Flexo Label Printer - Economical CI printing machine – Changhong

Special Price for Flexo Label Printer - Economical CI printing machine – Changhong Detail:

Machine Features

- Method:Central impression for better color registration. With the central impression con figuration,theprinted material is supported by the cylinder,and greatly improving color registration, especially with extensible materials.

- Structure: Wherever possible, parts are communized for availability and wear-resisting design.

- Dryer: Hot wind dryer, automatic temperature controller, and separated heat source.

- Doctor blade: Chamber doctor blade type assembly for high-speed printing.

- Transmission: Hard gear surface, high precision Decelerate Motor, and encoder buttons are placed on both control chassis and body for operations convenience.

- Rewind: Micro Decelerate Motor, drive Magnetic Powder and Clutch, with PLC control tension stability.

- Gearing of Printing cylinder: repeat length is 5MM.

- Machine Frame: 100MM thick iron plate. No vibration at high speed and have a long

Technical Specifications

| Model | CHCI-J (Customizable to fit production and market requirements) | |||

| Max. Web Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 150m/min | |||

| Printing Speed | 120m/min | |||

| Max. Unwind/Rewind Dia. | Φ 800mm/Φ1200mm/Φ1500mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

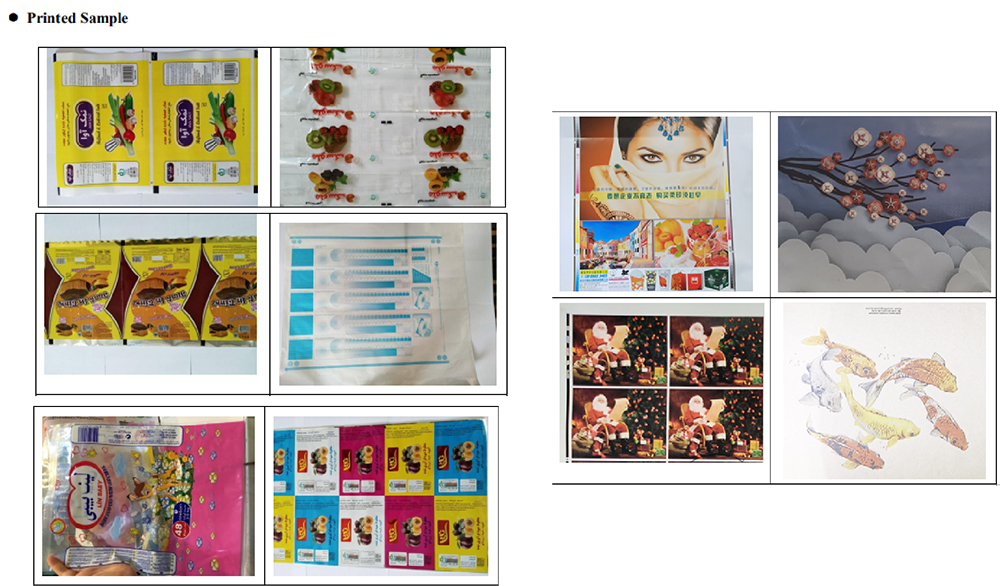

| Range Of Substrates | Film,PAPER,NONWOVEN, ALUMINUM FOIL | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

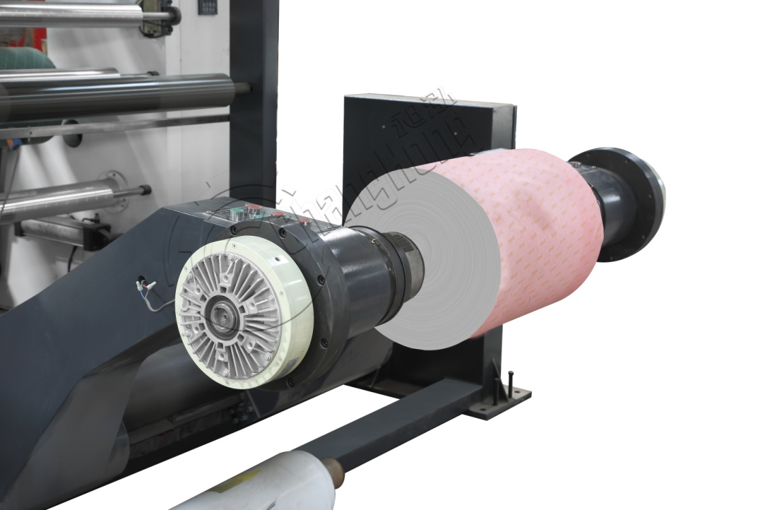

Single unwinder unit

- Max.unwinder diameter: Φ800mm

- Tension control: ±0.3kg

- Unwinder way: Single Central Unwind ; With 5KG magnetic power and automatic tension controller 1pcs

- EPC System for unwind : 1 set

- Unwind material holder: air shaft 3’’, 1 pcs

- Unwind web cylinder: Φ76mm (inner diameter)

Auto tension Controller -1 Set

- Without the influence of dust and dirt, it can control the tension towards different kinds of substrate. It can remain the machine’s tension stable as much as possible.

Web Guide -1Set

- In the process of the machine run, It can make the product aligned and correct the deviation of the coil in a timely manner.

Single Central Unwind

Option

Auto loading in unwinder

It’s easy to transport and loading material

Shaftless Unwinder

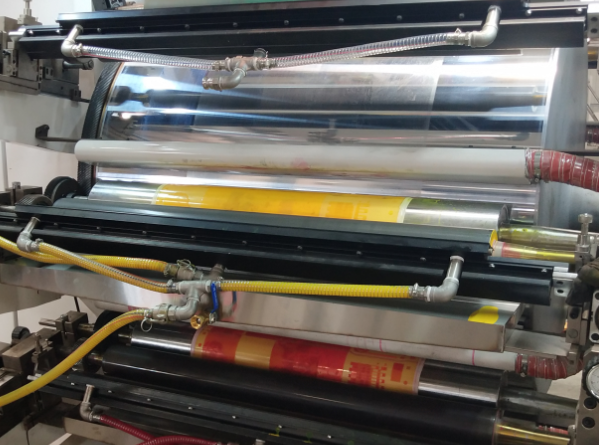

Printing Unit

- Type :Ci Type – Central drum

- Number of printing decks : 4/6 (one side printing, full width)

- Suitable Ink: Water-based ink or Oil-based ink

- Printing Plate: Resin or Rubber

- Constitution of Printing: Anilox roller, Rubber roller, Chrome plated roller, Printing cylinder, Resin version

- Anilox roller Cermaic: anilox roller (4/6pcs),Japan murata

- Printing cylinder 1 Set (4/6pcs)

- Plate rollers lifting By hydraumatic, when it start ,hydro-cylinder push ceramic anilox roller near the printing cylinder inking ,plate cylinder near to central drum printing, locked hydro-cylinder after printing.

- Printing Pressure: Mechanical adjust

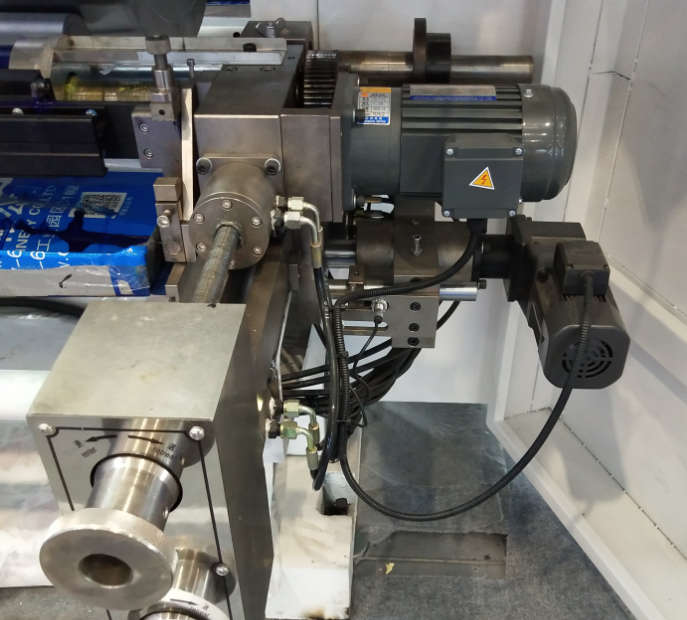

- Doctor blade : Enclosed Chamber doctor blades 4/6 pcs

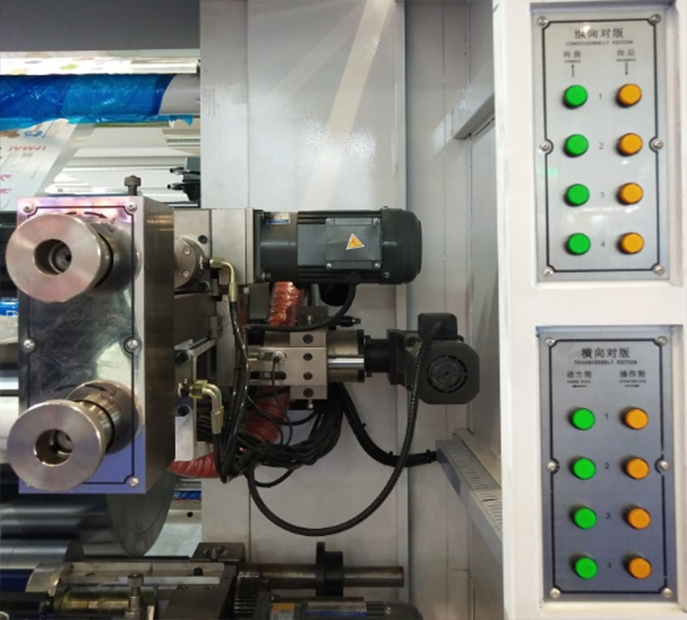

- Adjusting of Register: Motorized longitudinal registration and Motorized Transversal registration, PLC control

Printing cylinder—4/6pcs

- Within 40cm in the machine

- Printing repeat : 400-900mm

- Generally used for plate making, copper plating on the roller surface. Then engraving pattern, then coated with a layer of chromium. It usually used in

- plastic packaging.

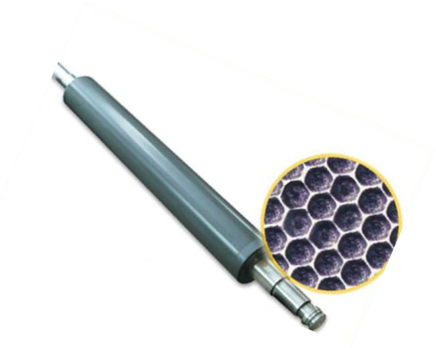

Ceramic Anilox roller -4/6 pcs

- Control the thickness of ink,transfer ink evenly

- Improve the printing quality

- As different material .choose different LPI for each unit (The best effect.200-800LPI )

- The precision of dynamic balancing: 10g.

- Automatic mixing the ink when halt machine.

Central Drum

- Diameter : Φ800mm/ Φ1200mm

- For the best color registration .with the central impression configuration .the printed material is supported by the cylinder. and greatly improving color registration .especially with extensible materials.

Enclosed chamber doctor blade -4/6 pcs

- With Two way cycle ink pump.no spill the ink . even the ink .save the ink

- Improve the printing quality

- Special for high speed printing pretend the ink splashing

Overhead crane -1 set

- Customer can choose manual crane or power crane.

- It’s easy to lift the materials

PLC System – 1 set

- Control machine and color register

Video Inspection – 1 set

- Check the printing quality on the video screen

Register adjustment By electric

- Motorized longitudinal registration and Motorized Transversal registration, PLC control

Heating and Drying unit

- Dryer on each color: Electrical heat drying .

- Double Blower way circle: Centralized heat, exhaust gas pump back.

Single rewind unit

- Max.rewinder diameter: Φ800mm

- Tension control: ±0.3kg

- Rewinder way: Center winder, with 10KG magnetic powder and clutch.

- Automatic tension controller 1pcs

- Rewind material holder: air shaft 3’’, 1 pcs

- Rewind web cylinder: Φ76mm (inner diameter)

- Rubber roller: Banana roller 1 pcs

Option

Surface rewind unit

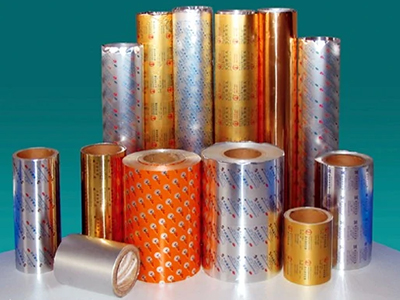

Main processed materials

Paper

Film

Non woven

Aluminum Foil

Product detail pictures:

Related Product Guide:

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of Special Price for Flexo Label Printer - Economical CI printing machine – Changhong , The product will supply to all over the world, such as: Anguilla, Ecuador, Dominica, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

Write your message here and send it to us