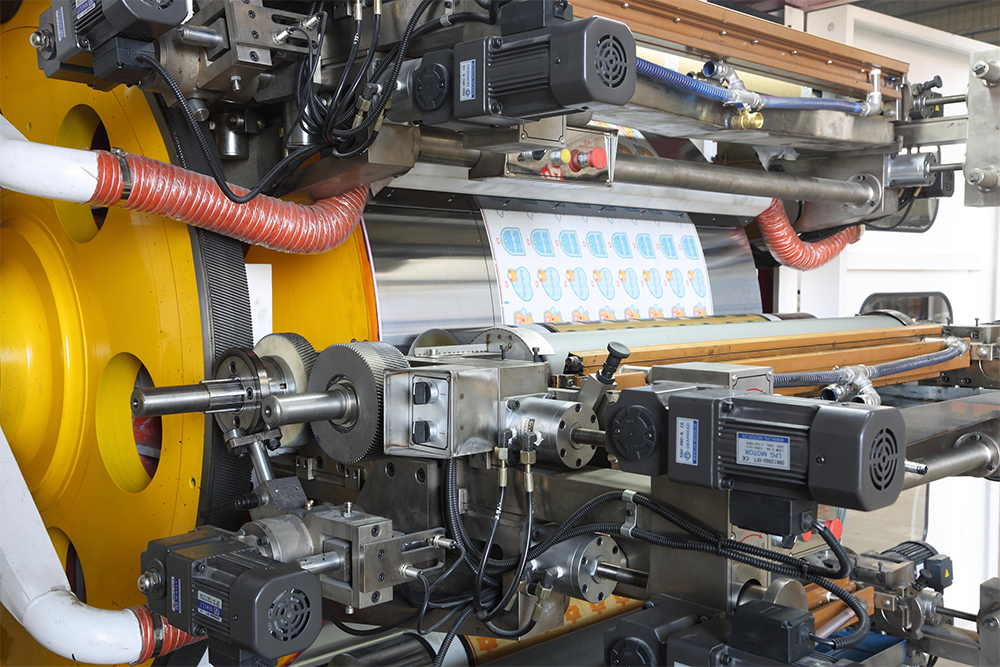

Quality Inspection for Ci Flexo Printing - 8 color CI printing machine for woven bag – Changhong

Quality Inspection for Ci Flexo Printing - 8 color CI printing machine for woven bag – Changhong Detail:

Characteristic

- The machine introduction & absorption of European technology / process manufacturing, supporting / full functional.

- After mounting the plate and registration, no longer need registration, improve yield.

- The machine first mount plate, pre-trapping function, to be completed in advance prepress trapping in the shortest possible time.

- The machine is equipped with blower and heater, and the heater employed central temperature control system.

- When machine stop, Tension can be maintained, the substrate is not deviation shift.

- The individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

- With precision structural, easy operation, easy maintenance, high degree of automation and so on, only one person can operate.

technical specifications

| Model | CHCI8-600E | CHCI8-800E | CHCI8-1000E | CHCI8-1200E |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 180m/min | |||

| Printing Speed | 120m/min | |||

| Max. Unwind/Rewind Dia. | φ1200mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-1200mm | |||

| Printing way | 4+4.4+3.4+2.4+1.4+0 Full width.Both side | |||

| Range Of Substrates | PP Woven | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Double station unwinding:

- Center-driven unwinding, equipped with magnetic powder brake, equipped with automatic tension control;

- Tension control: Ultra-light floating roller control, automatic tension compensation, closed loop control;(Low-friction cylinder position detection, precision pressure regulating valve control, automatic alarm or shutdown when the coil diameter reaches the set value)

- It has the function of automatic shutdown when the material is interrupted, and the tension maintains the function to avoid the substrate slack and deviation during the shutdown

- The outer diameter of the air expansion shaft is 3 inches, and the clamping method of the air expansion shaft is a 2-head cylinder release type.

- Configure automatic EPC system before printing

- EPC: Before printing, a four-roller automatic EPC ultrasonic probe correction system has manual/automatic/center return functions, and the left and right translation can be adjusted by ±65mm.

Printing Unit

- Type : CI Flex Printing Machine

- Color: 4 colors on the front + 4 colors on the back

- Drive mode: Servo gear drive

- Motor: Servo motor drive, inverter control closed loop control

- Printing method

hotosensitive resin plate, suitable for both water-based and alcohol-soluble inks

hotosensitive resin plate, suitable for both water-based and alcohol-soluble inks - Printing Repeat: 400-1200mm

Double station Rewinding

- Double-station Surface friction winding, Equipped with servo cutter, stable segment length

- The tension control adopts ultra-light floating roller control, automatic tension compensation, closed-loop control, and arbitrary setting of taper tension (low-friction cylinder position detection, precision pressure regulator control, automatic alarm or shutdown when the roll diameter reaches the set value)

- It has the function of automatic shutdown when the material is interrupted, and the tension maintains the function to avoid the substrate slack and deviation during the shutdown

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Quality Inspection for Ci Flexo Printing - 8 color CI printing machine for woven bag – Changhong , The product will supply to all over the world, such as: Turkey, Comoros, Mexico, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

Write your message here and send it to us