Quality Inspection for 4 Colors Plastic Bags Flexo Printing Press

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for Quality Inspection for 4 Colors Plastic Bags Flexo Printing Press, We give priority to high quality and customer fulfillment and for this we follow stringent good quality control measures. We have now in-house testing facilities where our goods are tested on every single aspect at different processing stages. Owning to latest technologies, we facilitate our shoppers with custom made manufacturing facility.

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for Flexo Printing Press and Plastic Bags Flexo Printing Press, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to “honest and trustworthy, favorable price, customer first”, so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

technical specifications

| Model | CH4-600H | CH4-800H | CH4-1000H | CH4-1200H |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 120m/min | |||

| Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Timing belt drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-1000mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

● Precise registration: One of the most remarkable features of the Stack Type Flexographic Printing Machine is its ability to provide precise registration. The machine uses advanced technology to ensure that all colors align perfectly, resulting in crisp, clear prints.

● High-Speed Printing:This printing machine can handle high-speed printing, which allows the user to print large volumes of materials within a short period. This feature makes it ideal for commercial printing purposes.

● Versatile Printing Options: Another unique feature of the Stack Type Flexographic Printing Machine is its ability to print on a wide variety of materials, including paper, plastic, and fabric. It can handle materials of different thickness and texture with ease.

● User-Friendly Design:These machines come with a user-friendly design that makes it easy to operate. The control panel is simple to navigate, and the machine can be easily adjusted to suit different printing needs.

● Low Maintenance: These machines require little maintenance, which is one of their biggest advantages. With proper care and regular cleaning, Stack Type Flexographic Printing Machines can last for years without showing any signs of wear and tear.

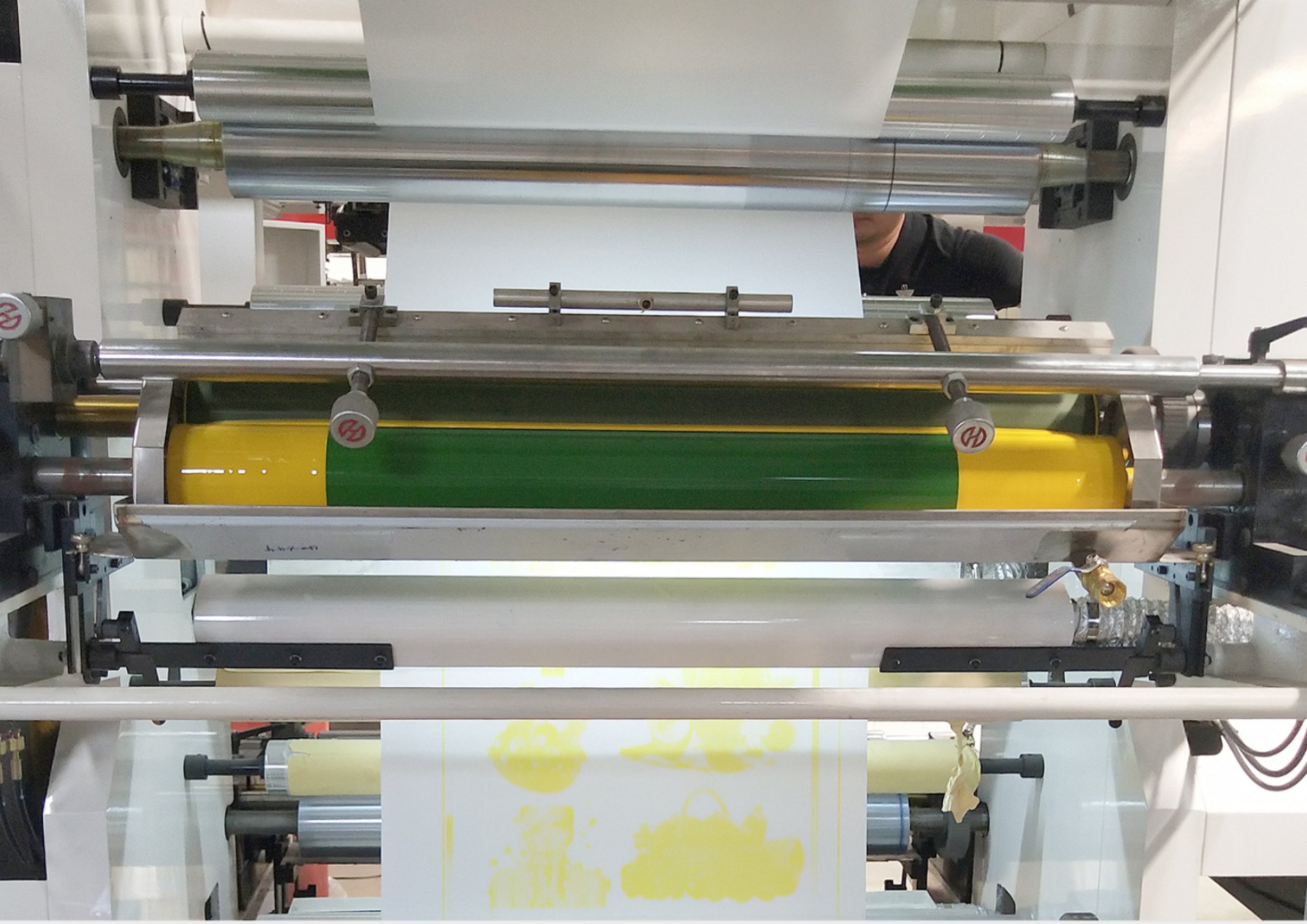

Details Dispaly

Options

Check the printing quality on the video screen.

prevent fading after printing.

With two way cycle ink pump, no spill the ink, even the ink, save the ink.

Printing two roller at the same time.

sample

Packaging and Delivery

FAQ

Q: What is your after-sale service?

A: We have been in flexo printing machine business for many years, we will send our professional engineer to install and test machine.

Beside, we can also provide online support, video technical support, matching parts delivery, etc. So our after-sales services is always reliable.

Q: What services do you have?

A: 1 Year Guarantee !

100% Good Quality !

24 Hours online Service!

The buyer paid tickets ( go and back to FuJian), and pay 150usd/day during the install and testing period!

Q:What is a flexographic printing machine?

A: A flexographic printing machine is a printing press that uses flexible relief plates made of rubber or photopolymer to produce high-quality print results on various types of substrates. These machines are widely used in printing on a variety of materials including paper, plastic, non- woven, etc.

Q:How does a flexographic printing machine work?

A:The flexographic printing machine uses a rotating cylinder that transfers ink or paint from a well onto a flexible plate. The plate then comes into contact with the surface to be printed, leaving the desired image or text on the substrate as it moves through the machine.

Q:What types of materials can be printed using a stack flexographic printing machine?

A stack flexographic printing machine can print on a variety of materials including plastic, paper, film, foil, and non-woven fabrics, among others.

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for Quality Inspection for 4 Colors Plastic Bags Flexo Printing Press, We give priority to high quality and customer fulfillment and for this we follow stringent good quality control measures. We have now in-house testing facilities where our goods are tested on every single aspect at different processing stages. Owning to latest technologies, we facilitate our shoppers with custom made manufacturing facility.

Quality Inspection for Flexo Printing Press and Plastic Bags Flexo Printing Press, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to “honest and trustworthy, favorable price, customer first”, so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!