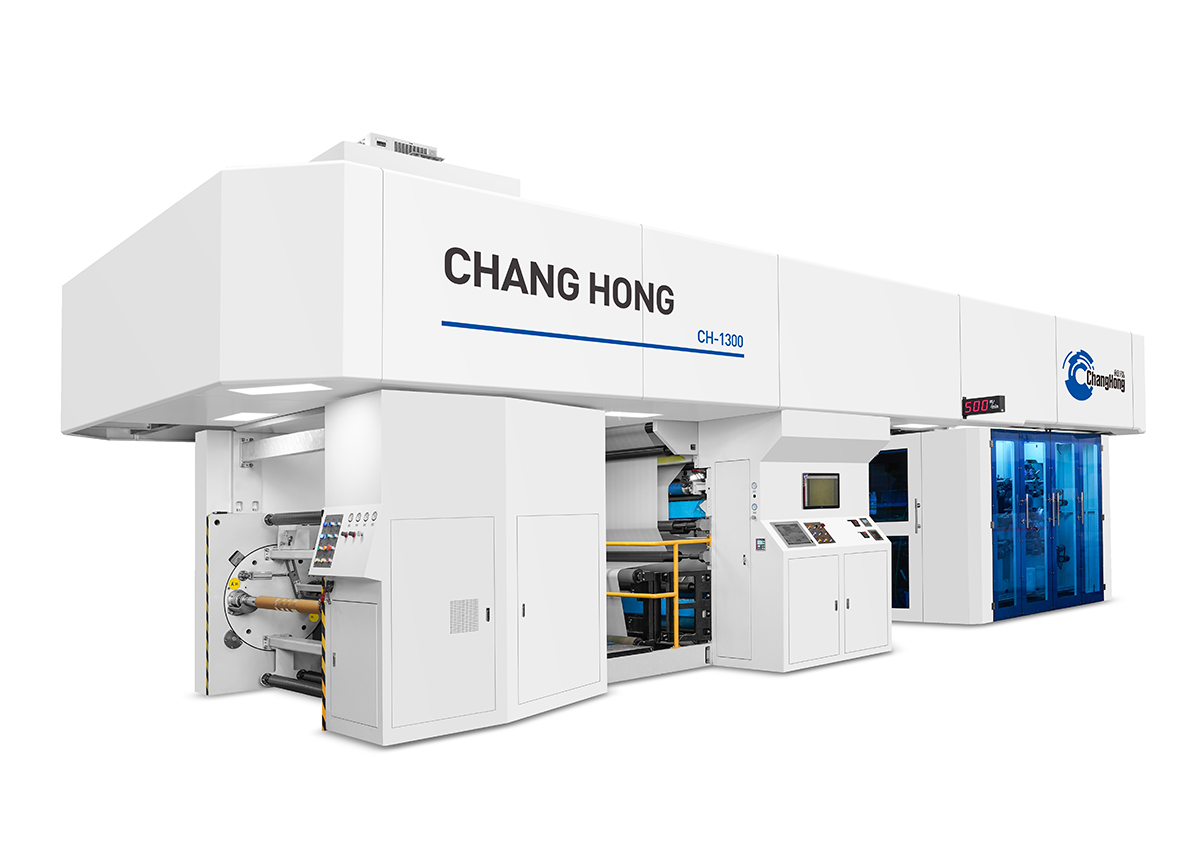

Medium width Gearless CI flexographic printing machine 500m/min

The system eliminates the need for gears and reduces the risk of gear wear, friction and backlash.The Gearless CI flexographic printing machine minimizes waste and environmental impact. It uses water-based inks and other environmentally friendly materials, reducing the carbon footprint of the printing process. It features an automatic cleaning system that reduces the time and effort required for maintenance.

8 Color CI Flexo Machine for PP/PE/BOPP

CI Flexo Machine inked impression is achieved by pressing a rubber or polymer relief plate against the substrate, which is then rolled across the cylinder. Flexographic printing is widely used in the packaging industry due to its speed and high-quality results.

4 Colour CI Flexo Printing Machine

CI Flexo Printing Machine is a popular high-performance printing machine designed specifically for printing on flexible substrates. It is characterized by high-precision registration and high-speed production. It is mainly used for printing on flexible materials such as paper, film and plastic film. The machine can produce a wide range of printing such as flexo printing process, flexo label printing etc. It is widely used in the printing and packaging industry.

4+4 Color CI Flexo machine For PP Woven Bag

The advanced control system of this PP woven bag CI Flexo Machine can achieve the process control of automatic error compensation and creep adjustmen. To make PP woven bag, we need special Flexo Printing Machine which is made for PP woven bag. It can print 2 colors, 4 colors or 6 colors on the surface of PP woven bag.

Economical CI printing machine

Flexo Printing Machine short for central impression flexography, is a printing method that uses flexible plates and a central impression cylinder to produce high-quality, large-scale prints on a variety of materials. This printing technique is commonly used for labeling and packaging applications, including food packaging, beverage labeling, and more.

NON STOP STATION CI FLEXOGRAPHIC PRINTING PRESS

One of the key advantages of this printing press is its non-stop production capability. The NON STOP STATION CI flexographic printing press has an automatic splicing system that enables it to print continuously without any downtime. This means that businesses can produce larger volumes of printed materials in a shorter amount of time, enhancing productivity and profitability.

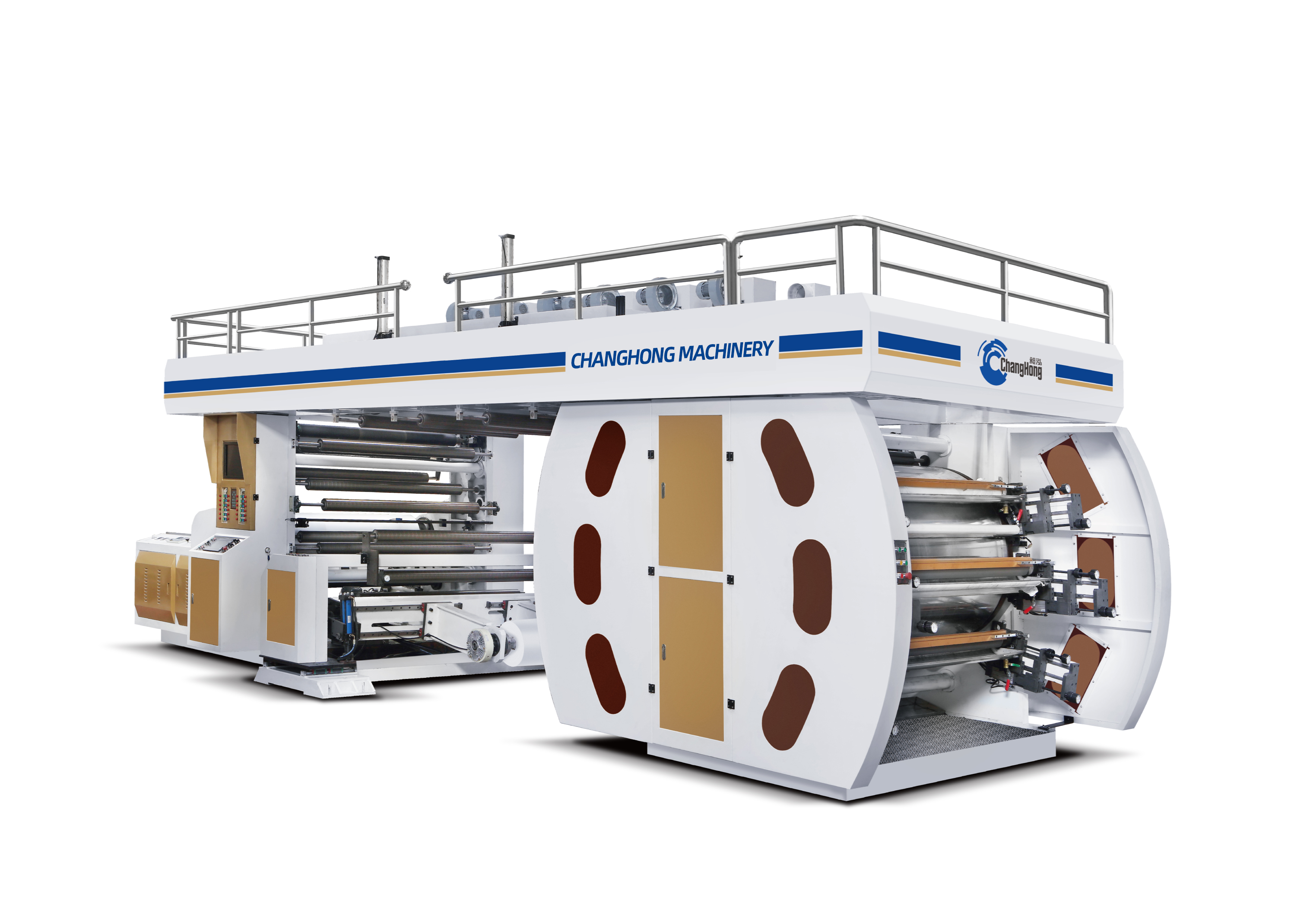

6 Colour Stack Flexo Printing Machine

Stack flexo printing machine is an advanced printing device that is capable of producing high-quality, spotless prints on a variety of materials. The machine is equipped with a number of features that enable the printing of various processes and production scenarios. It also offers great flexibility in terms of speed and print size. This machine is ideal for printing high-end labels, flexible packaging, and other applications requiring intricate, high-resolution graphics.

4 COLOUR GEARLESS CI FLEXO PRINTING PRESS

Gearless flexo printing press is a type of flexographic printing press that does not require gears as part of its operations. The printing process for a gearless flexo press involves a substrate or material being fed through a series of rollers and plates that then apply the desired image onto the substrate.

Central Drum 8 Color Ci Flexo Machine

CI Flexo Printing Machine is a popular high-performance printing machine designed specifically for printing on flexible substrates. It is characterized by high-precision registration and high-speed production. It is mainly used for printing on flexible materials such as paper, film and plastic film. The machine can produce a wide range of printing such as flexo printing process, flexo label printing etc. It is widely used in the printing and packaging industry.

6 Color CI Flexo Machine For Plastic Film

CI Flexo Printing Machine is a type of printing press that uses a flexible relief plate to print on various types of substrates, including paper, film, plastic, and metal foils. It works by transferring an inked impression onto the substrate through a rotating cylinder.

8 Colour Stack Flexo Printing Machine

The Flexo Stack Press is an automated printing system designed to help businesses of any size increase their printing capacity and improve product safety.Its robust, ergonomic design allows for easy maintenance and reliable operation. The stack press can be used to print on flexible plastics and paper.

Central Drum 6 Color CI Flexo Printing Machine For Paper Products

Central Drum Flexo Printing Machine is an advanced Flexo printing machine that can print high quality graphics and images on different types of substrates, with speed and accuracy. Suitable for flexible packaging industry. It is designed to quickly and efficiently print on substrates with high accuracy, at very high production speeds.