Products

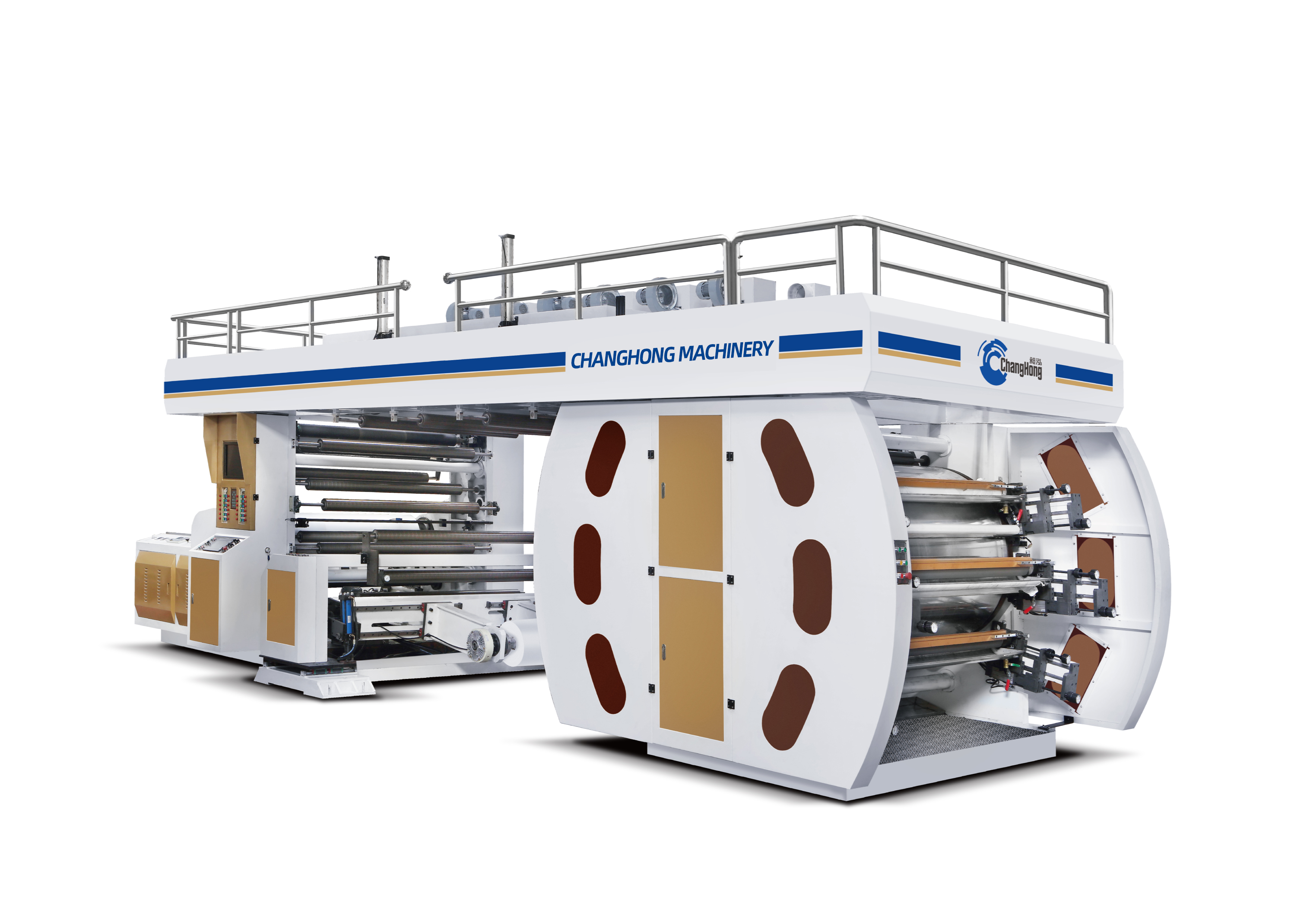

4 COLOR FLEXO PRINTING MACHINE/CI FLEXOGRAPHIC PRINTING PRESS FOR PP WOVEN BAG

This 4 color ci flexographic printing press is specially designed for PP woven bags. It adopts advanced central impression technology to achieve high-speed and precise multi-color printing, suitable for various packaging production such as paper and woven bags. With features like energy efficiency, environmental friendliness, and user-friendly operation, it is the ideal choice for enhancing packaging printing quality.

NON WOVEN/NON WOVEN BAGS ROLL TO ROLL CI FLEXO PRINTING MACHINE

The CI flexographic printing machine for nonwoven fabrics is an advanced and efficient tool that allows for high print quality and fast, consistent production of products. This machine is especially suitable for printing nonwoven materials used in the manufacture of products such as diapers, sanitary pads, personal hygiene products, etc.

6+1 color gearless ci flexo printing machine/flexographic printer for paper

This CI flexo printing machine features advanced gearless full servo drive technology, engineered for high-efficiency, high-precision paper printing. With a 6+1 color unit configuration, it delivers seamless multi-color overprinting, dynamic color accuracy, and exquisite precision in intricate designs, meeting diverse demands in,paper, non-woven fabrics, food packaging, and more.

HIGH SPEED DUAL-STATION NON-STOP GEARLESS FLEXOGRAPHIC PRINTING MACHINES ROLL TO ROLL 6 COLOR

Our high-speed dual-station gearless flexographic printing machines is an advanced equipment specifically designed for high-efficiency and high-precision printing needs. It adopts gearless full servo drive technology, supports roll-to-roll continuous printing, and is equipped with 6 color printing units to meet diverse color and complex pattern printing requirements. The dual-station design enables non-stop material changing, significantly improving production efficiency. It is an ideal choice for industries such as labeling and packaging.

8 COLOUR GEARLESS CI FLEXO PRINTING PRESS

Full servo flexo printing machine is a high-quality printing machine used for versatile printing applications. It has a wide range of applications including paper, film,Non Woven other various materials. This machine has a full servo system that makes it produce highly accurate and consistent prints.

STACK FLEXO PRESS FOR PLASTIC FILM

One of the biggest advantages of a stack flexo press is its ability to print on thin, flexible materials. This produces packaging materials that are lightweight, durable and easy to handle. In addition, stack flexo printing machines are also environmentally friendly.

NON-WOVEN STACKED FLEXOGRAPHIC PRESSES

The Stack Flexo Printing Machine for non-woven products is a remarkable innovation in the printing industry. This machine is designed to enable seamless and efficient printing of non-woven fabrics with precision. Its printing effect is clear and attractive, making non-woven materials attractive and attractiveness.

Stack type flexo printing machine for paper

One of the most significant advantages of the stack type flexo printing machine is ability to print with precision and accuracy. Thanks to its advanced registration control system and cutting-edge plate mounting technology, it ensures exact color matching, sharp imagery, and consistent print results.

Central Drum 8 Color Ci Flexo Machine

CI Flexo Printing Machine is a popular high-performance printing machine designed specifically for printing on flexible substrates. It is characterized by high-precision registration and high-speed production. It is mainly used for printing on flexible materials such as paper, film and plastic film. The machine can produce a wide range of printing such as flexo printing process, flexo label printing etc. It is widely used in the printing and packaging industry.

SHAFTLESS UNWINDING 6 COLOR CI FLEXOGRAPHIC PRINTING MACHINERY/CENTRAL IMPRESSION FLEXO PRESS FOR PAPER CUP/PAPER BAG

This Shaftless Unwinding 6 color ci flexographic printing machine is specifically designed for high-efficiency printing of paper cups, paper bags, and other packaging products. It incorporates advanced central impression cylinder technology and a shaftless unwinding system to achieve high-precision register, stable tension control, and quick plate changes. It meets the stringent demands of industries such as food packaging and daily-use paper products for high color reproduction accuracy and precise register.

FFS HEAVY-DUTY FILM FLEXO PRINTING MACHINE

One of the key features of the FFS Heavy-Duty Film Flexo Printing Machine is its ability to print on heavy-duty film materials with ease. This printer is designed to handle high-density polyethylene (HDPE) and low-density polyethylene (LDPE) film materials, ensuring that you get the best printing results on any material that you choose.

6 color central drum ci Flexo Printing Machine for PE/PP/ PET/PVC

This ci flexo printing machine is specially designed for film printing. It adopts central imprinting technology and intelligent control system to achieve precise overprinting and stable output at high speed, helping to upgrade the flexible packaging industry.