NON WOVEN/NON WOVEN BAGS ROLL TO ROLL CI FLEXO PRINTING MACHINE

technical specifications

| Model | CHCI4-600J-NW | CHCI4-800J-NW | CHCI4-1000J-NW | CHCI4-1200J-NW |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max. Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

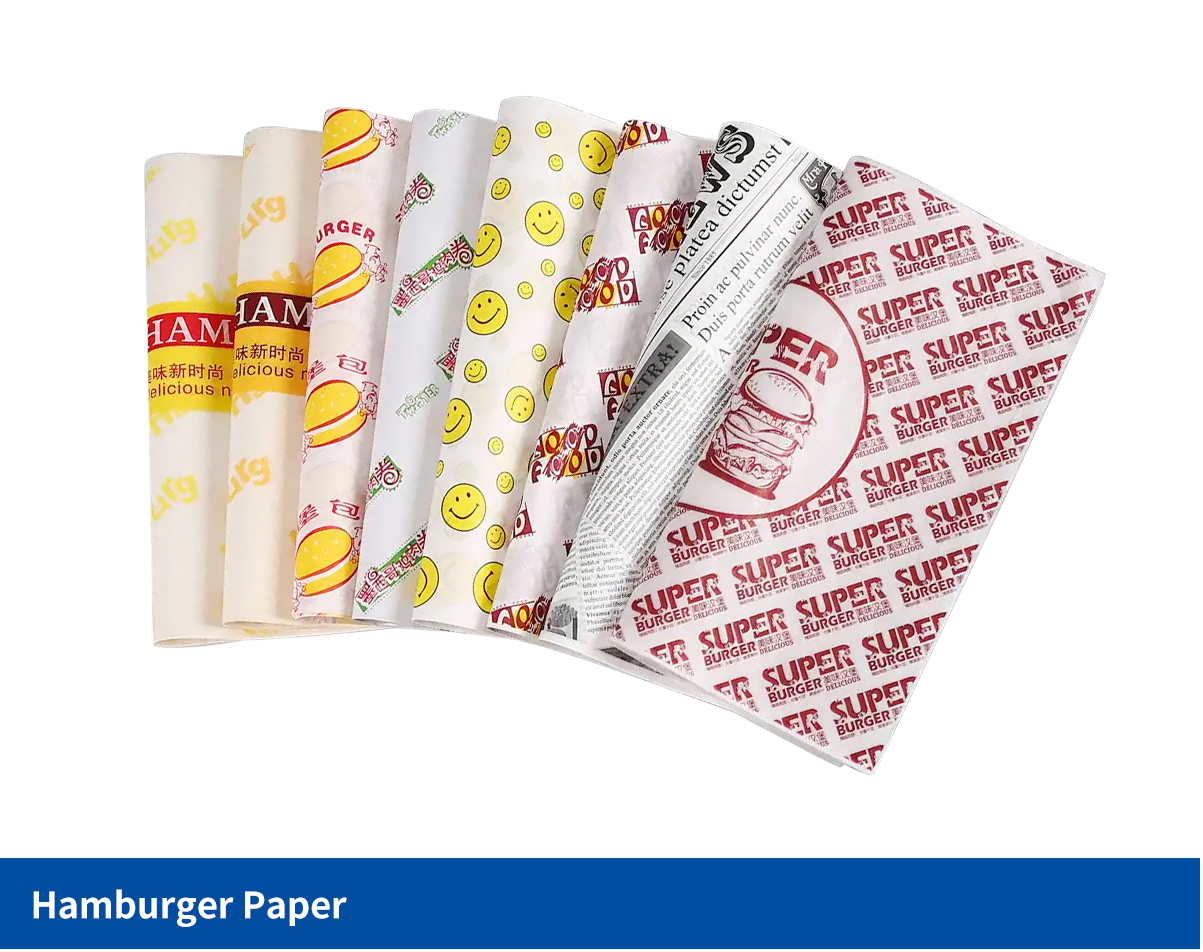

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

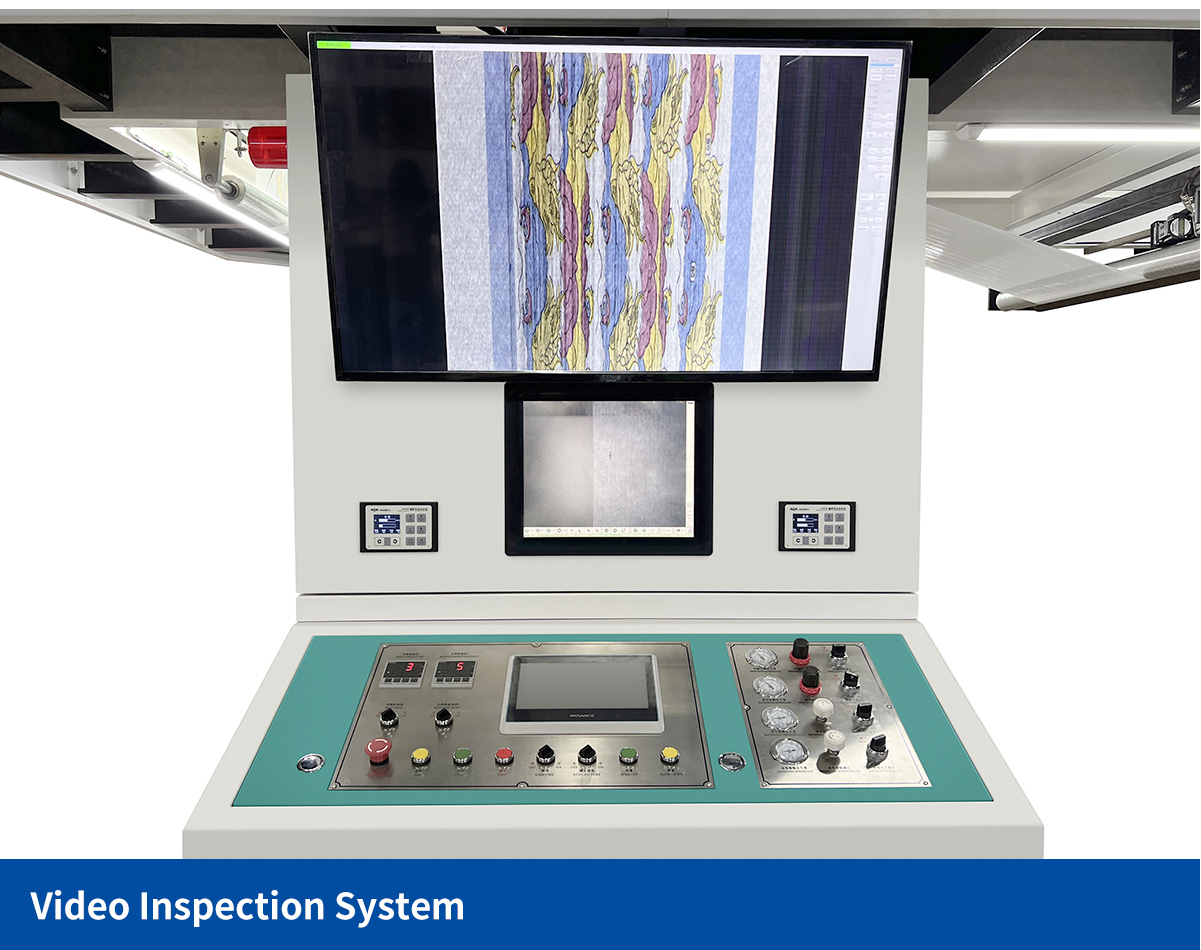

Video Introduction

Machine Features

1. High Print Quality: The CI nonwoven flexographic printing machine can print high-quality designs and fine details with maximum precision. In addition, the machine also has the ability to print on various nonwoven substrates and other materials such as metals, plastics, and paper.

2. Fast Production: Thanks to its high-volume production capacity, the CI nonwoven flexographic printing machine is a popular choice for mass production of nonwoven products. In addition, its production speed is much faster than other printing options, allowing for faster production and decreased lead times.

3. Automatic Registration System: The modern technology used in the CI nonwoven flexographic printing machine has an automatic registration system that allows for precision in the alignment and repetition of the printing designs and patterns. This ensures more uniform and consistent production.

4. Low Production Cost: With the ability to produce large quantities of nonwoven products at a fast speed, the CI nonwoven flexographic printing machine enables mass production that helps reduce costs in the production process.

5. Easy Operation: The CI nonwoven flexographic printing machine is designed to be easy to use and operate, meaning that little time and effort is required to get it up and running. This reduces production errors caused by lack of experience in operating the machine.

Details Dispaly

sample

Packaging and Delivery