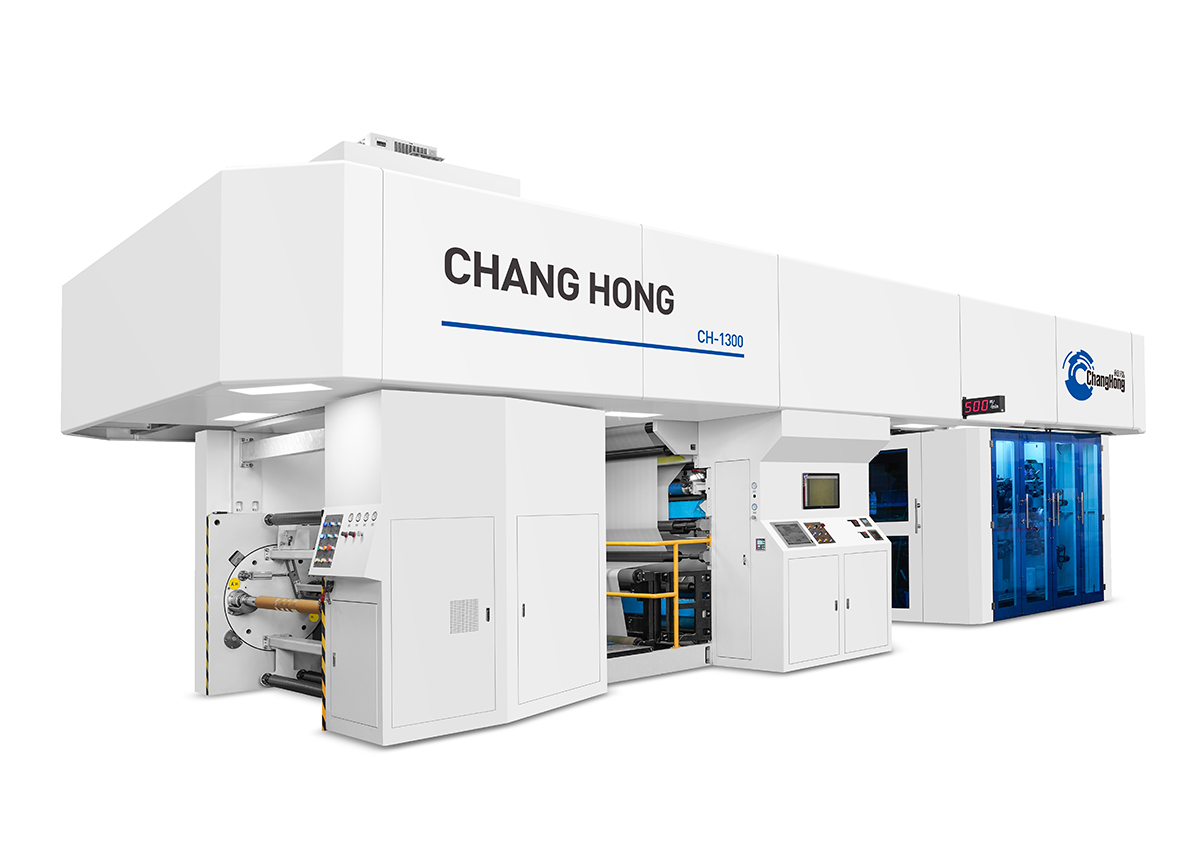

NON-WOVEN STACKED FLEXOGRAPHIC PRESSES

technical specifications

| Model | CH4-600B-NW | CH4-800B-NW | CH4-1000B-NW | CH4-1200B-NW |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High-quality printing: Stacked flexographic presses are capable of producing high-quality prints that are sharp and vibrant. They can print on a variety of surfaces, including paper, film, and foil.

2. Speed: These presses are designed for high-speed printing, with some models capable of printing up to 120m/min. This ensures that large orders can be completed quickly, thereby increasing productivity.

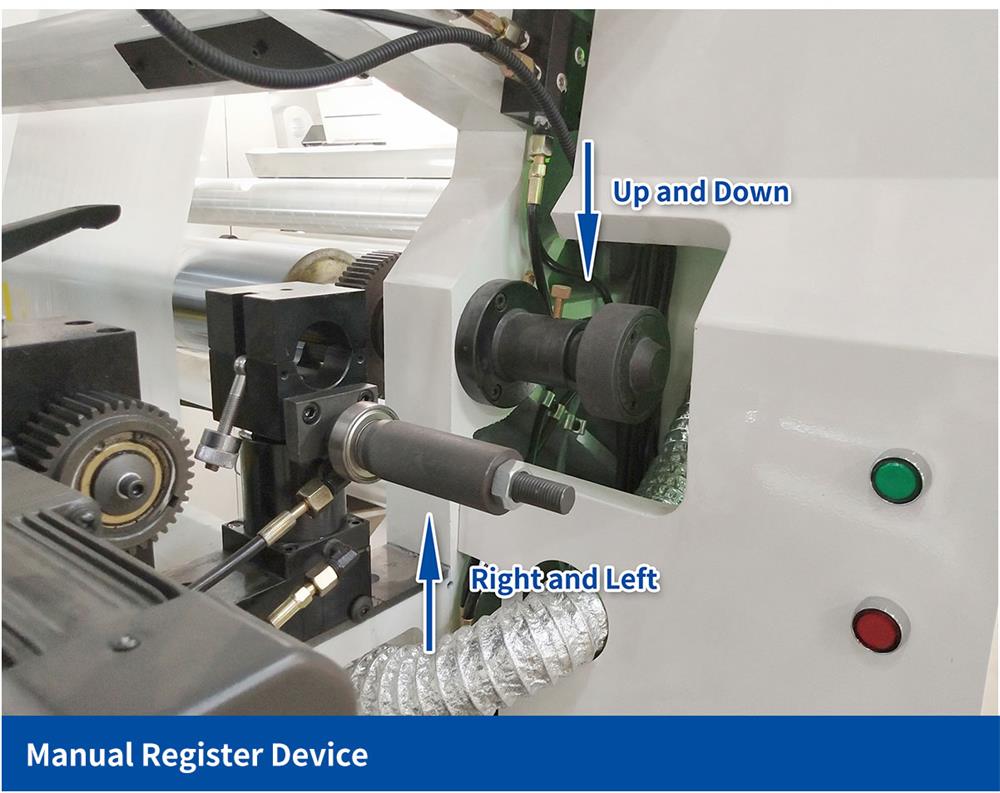

3. Precision: Stacked flexographic presses can print with high precision, producing repeatable images that are perfect for brand logos and other intricate designs.

4. Integration: These presses can be integrated into existing workflows, reducing downtime and making the printing process more streamlined.

5. Easy maintenance: Stacked flexographic presses require minimal maintenance, making them easy to use and cost-effective in the long run.

Details Dispaly

sample