The 4-color paper stacking flexographic printing machine is an advanced tool that has been developed to improve efficiency and quality in the printing and packaging processes of products in today's market. This machine features state-of-the-art technology that allows the printing of up to 4 different colors in a single pass, which translates into a significant increase in the speed and productivity of the process.

●Technical Parameters

| Model | CH4-600B-Z | CH4-800B-Z | CH4-1000B-Z | CH4-1200B-Z |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink olvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

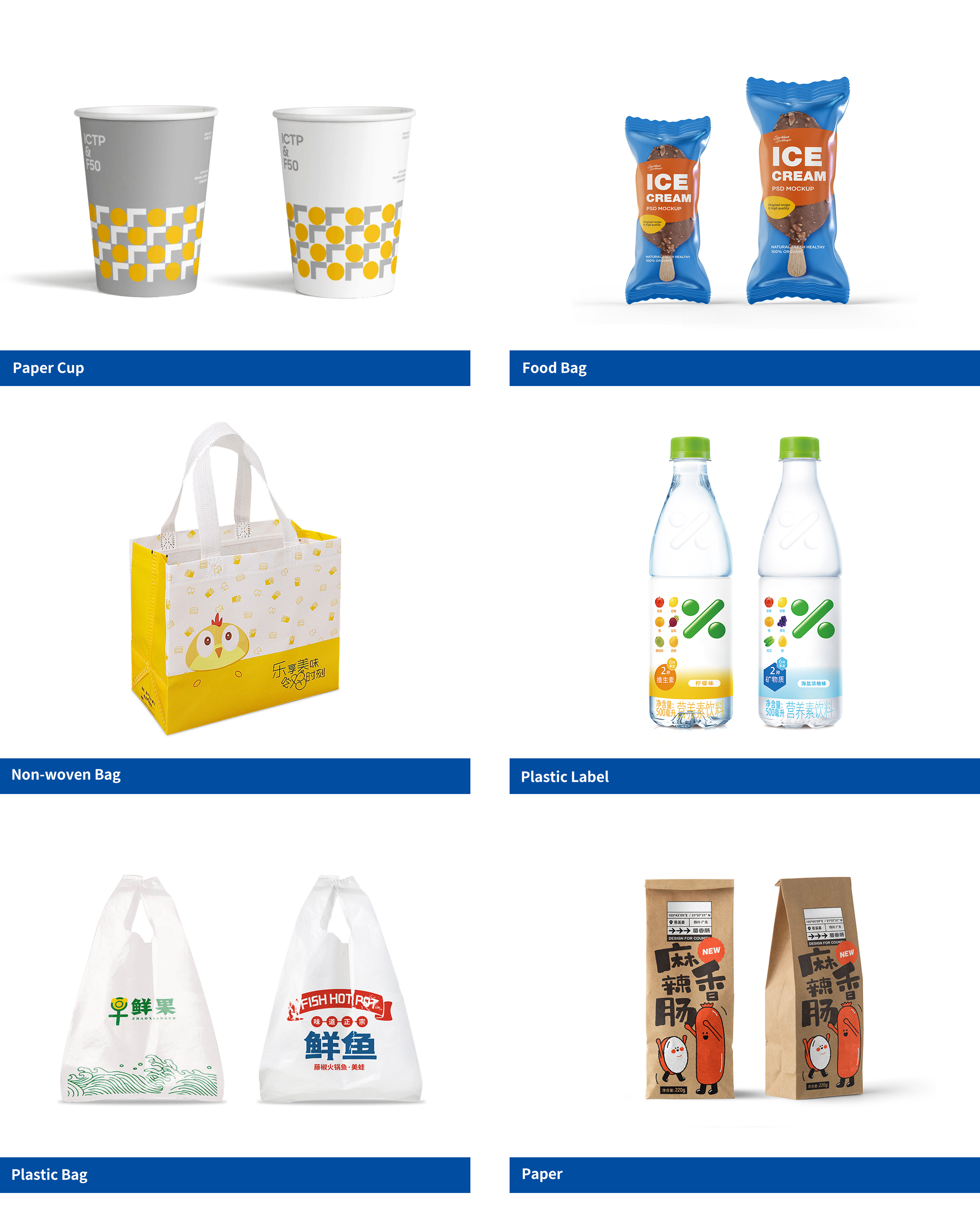

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

●Video Introduction

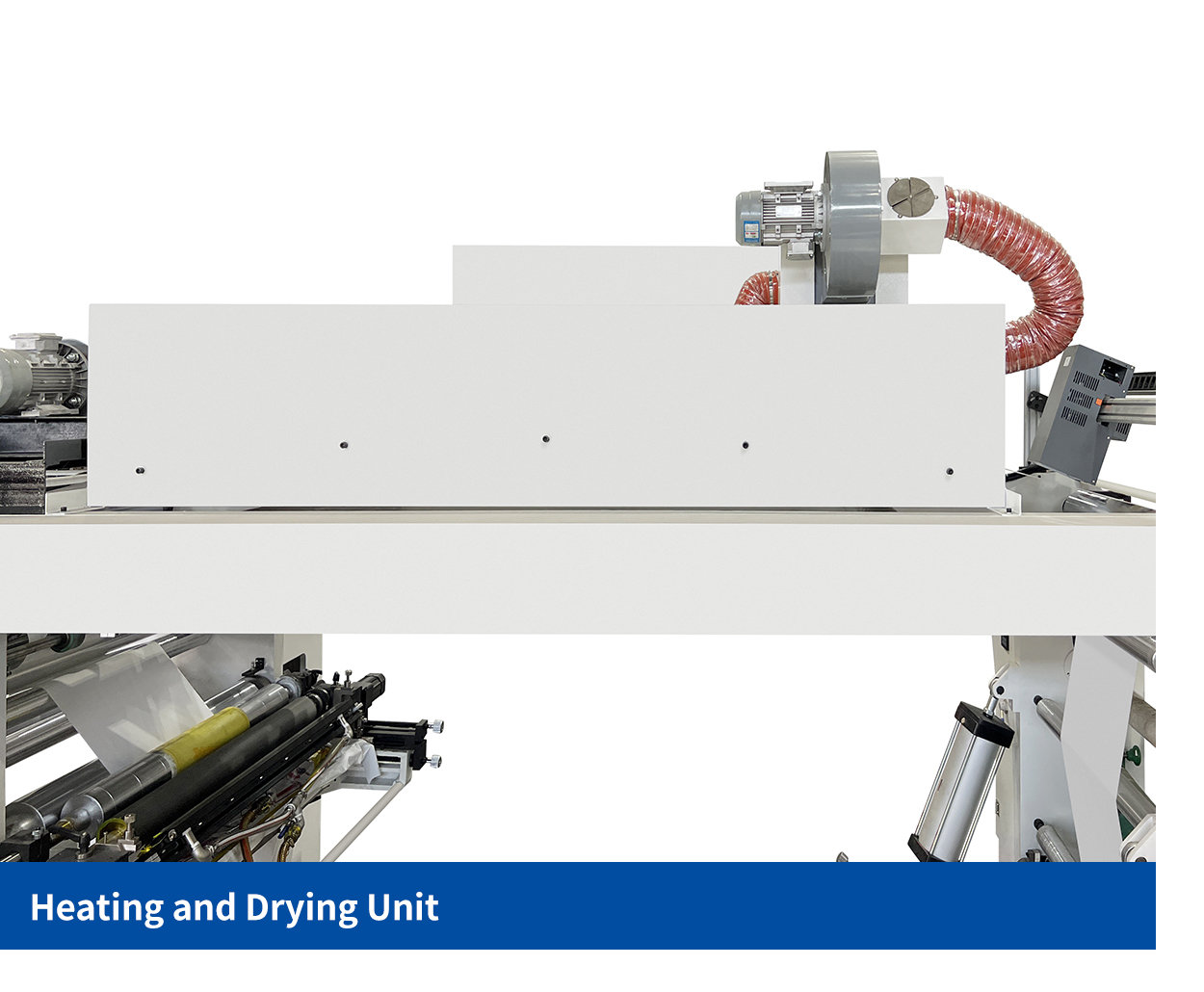

●Machine Features

The 4 Color Paper Stack Flexo Printing Machine has a large capacity to handle large quantities of paper of different sizes and thicknesses is a very useful tool for the efficient and high-quality production of laminated products. Here are some of its features:

1. Large capacity: The 4 Color Stack Flexo Printing Machine has a large capacity to handle large quantities of paper of different sizes and thicknesses.

2. High speed: The machine can work at high speed, which helps companies increase their production capacity and improve their efficiency.

3. Vibrant colors: The machine is capable of printing in 4 different colors, ensuring that the laminated products have vibrant colors and excellent print quality.

4. Time and cost saving: Using a 4-color paper satck printing machine can help reduce costs and production time as it allows printing and laminating in one step.

●Detailed image

●Sample

Post time: Dec-30-2024