Double unwinder and rewinder flexo printing machine offer a host of advantages to businesses in the packaging and labeling industry. These machines are designed to handle large volumes of printing tasks with high precision and accuracy, making them ideal for businesses with a high demand for labeling and packaging solutions. Here are some of the key advantages of using double unwinder and rewinder flexo printing machines:

Video Introduction

Advantage

| Model | CH6-600B-S | CH6-800B-S | CH6-1000B-S | CH6-1200B-S |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ600mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

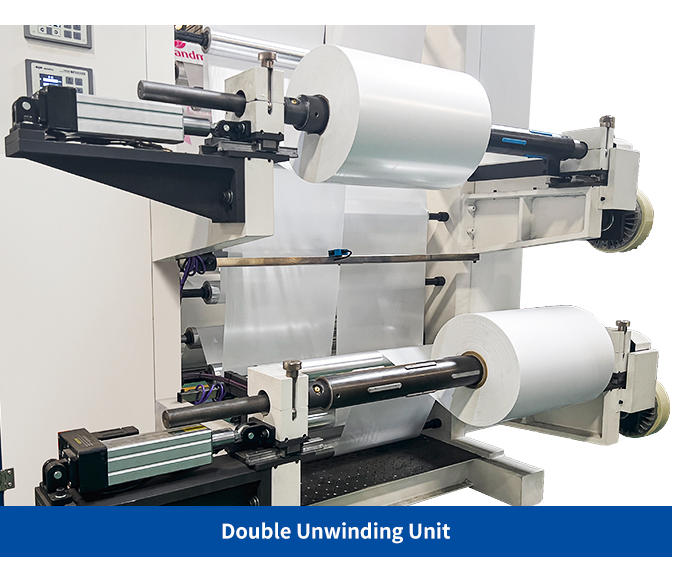

1. Increased productivity: One of the key advantages of using a double unwinder and rewinder flexo printing machine is the increased productivity it offers. These machines are equipped with multiple unwinding and rewinding stations, which allows for continuous printing and reduces downtime. This translates to increased throughput, higher output and faster turnaround times.

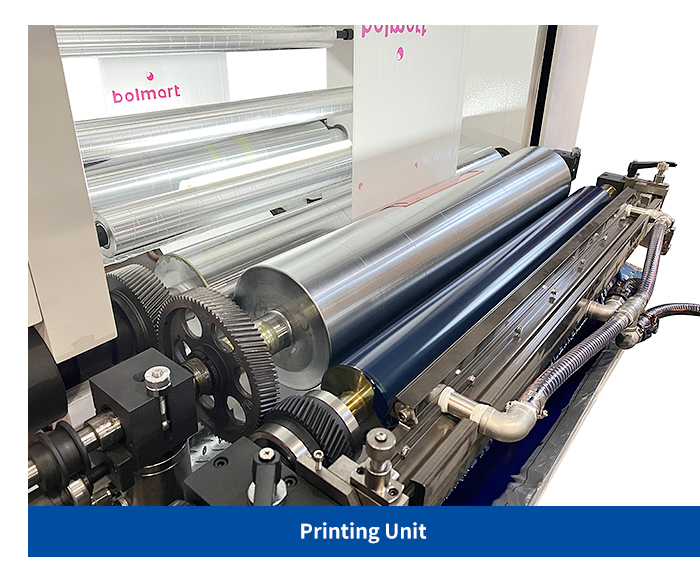

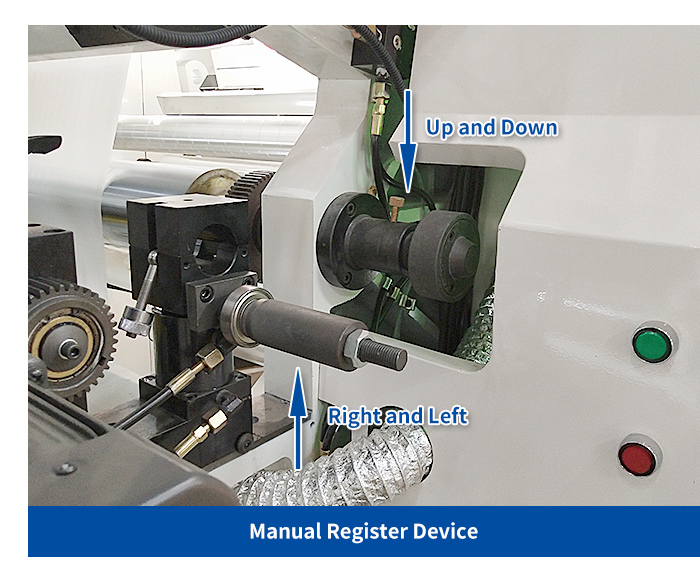

2. High precision printing: Double unwinder and rewinder flexo printing machines are designed to provide high precision printing. They come with advanced control systems that ensure precise control of the printing process, including ink flow, registration and color management.

3. Versatility: Another key advantage of double unwinder and rewinder flexo printing machines is their versatility. They can handle a wide range of label and packaging substrates, including paper, film, foil and more. This makes them ideal for businesses that need to print on different types of materials.

4. Time and cost savings: Using a double unwinder and rewinder flexo printing machine can save businesses both time and money. These machines are automated and require minimal human intervention, which reduces the labor costs associated with manual printing.

5. Improved efficiency: Finally, using a double unwinder and rewinder flexo printing machine can improve overall operational efficiency. These machines are equipped with advanced monitoring and control systems that allow for real-time tracking of the printing process. This helps to identify and resolve potential issues early, reducing the risk of downtime and improving process efficiency.

In conclusion, double unwinder and rewinder flexo printing machines offer a wide range of benefits to businesses in the packaging and labeling industry. From increased productivity and high precision printing to versatility, time and cost savings, and improved efficiency, these machines are a valuable investment for any business looking to streamline their printing operations and improve their bottom line.

Details

Post time: Jun-24-2024