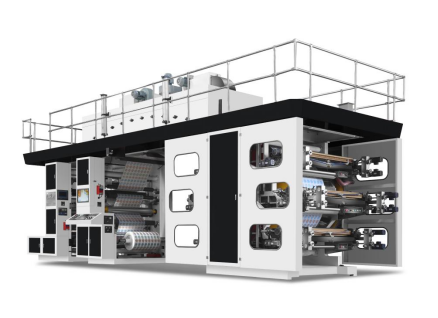

The Central Drum of the Cl Flexo Printing Press can be used as a fixed component of the pressure regulating unit. In addition to the operation of the main body, its horizontal position is fixed and stable. The changing unit on the printing color group is close to or isolated from the central roller. Achieve pressure control on printing materials. The central drum is directly driven by a Siemens torque motor. The most obvious thing is that the traditional servo motor with a reduction box is removed. The design advantage of this direct drive is: relative to the small moment of inertia, large torque transmission, the water cooling system can Improved rated power, large overload capacity, high dynamic response and high printing accuracy.

●Technical Specifications

| Model | CHCI6-600E-S | CHCI6-800E-S | CHCI6-1000E-S | CHCI6-1200E-S |

| Max. Web Width | 700mm | 900mm | 1100mm | 1300mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink olvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V.50 HZ.3PH or to be specified | |||

●Video Introduction

●Unwinding unit

Ci flexo machine unwinding part adopts an independent turret bidirectional rotation dual-axis dual-station structure design, which can change materials without stopping the machine. It is simple to operate, saves time and materials; in addition, the PLC automatic control design can effectively reduce human interference and improve cutting accuracy; The automatic detection design of the roll diameter avoids the disadvantages of manual input when changing rolls. The roll diameter detection device is used to automatically detect the diameter of the new roll. The tension detection system design controls the forward and reverse rotation of the motor, which can effectively Control system tension.

●Printing unit

Reasonable guide roller layout enables the film material to run smoothly; the sleeve plate change design greatly improves the speed of plate change and ensures extremely high printing efficiency; the closed scraper reduces solvent evaporation and stabilizes the viscosity, which not only avoids ink splashing, but also It can ensure stable printing viscosity; the ceramic anilox roller has high transfer performance, the ink is even and smooth, and is sturdy and durable; the human-machine interface interacts with the PLC to automatically control the lifting after setting the data.

●Rewind unit

Dual-axis dual-motor drive, non-stop material change, simple operation, saving time and material; PLC and photoelectric switch automatically control and detect the precise position of cutting, reducing errors and difficulties caused by manual operation, and improving the success of cutting efficiency; the buffer roller design effectively avoids excessive impact during tape transfer and reduces tension fluctuations; the roll changing process is controlled by a PLC program to ensure that it is synchronized with the host speed; the independent rotary frame has high processing accuracy and is easy to operate; the winding The taper tension adopts closed-loop feedback automatic control to ensure consistent tension inside and outside the roll and prevent wrinkles in the rolled film material.

●Central Drying system

The drying system has a high-efficiency and low-solvent residual structure, and the product has low solvent residue; the oven adopts a negative pressure design to prevent hot air from flowing out, and the temperature is automatically controlled with high precision; low temperature and high air volume can form an air shovel, which is highly energy-saving.

Post time: May-20-2024