The polyethylene flexographic printing machine is an essential tool in the production of high-quality packaging. It is used to print custom designs and labels on polyethylene materials, making them water-resistant and scratch-resistant.

This machine is designed with advanced technology that ensures high efficiency and quality in the production of packaging. With this machine, companies can print custom designs in large quantities, allowing them to reduce costs and increase their capacity to meet market demand.

●Technical Specifications

| Model | CHCI6-600E-S | CHCI6-800E-S | CHCI6-1000E-S | CHCI6-1200E-S |

| Max. Web Width | 700mm | 900mm | 1100mm | 1300mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink olvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V.50 HZ.3PH or to be specified | |||

●Video Introduction

●Machine Features

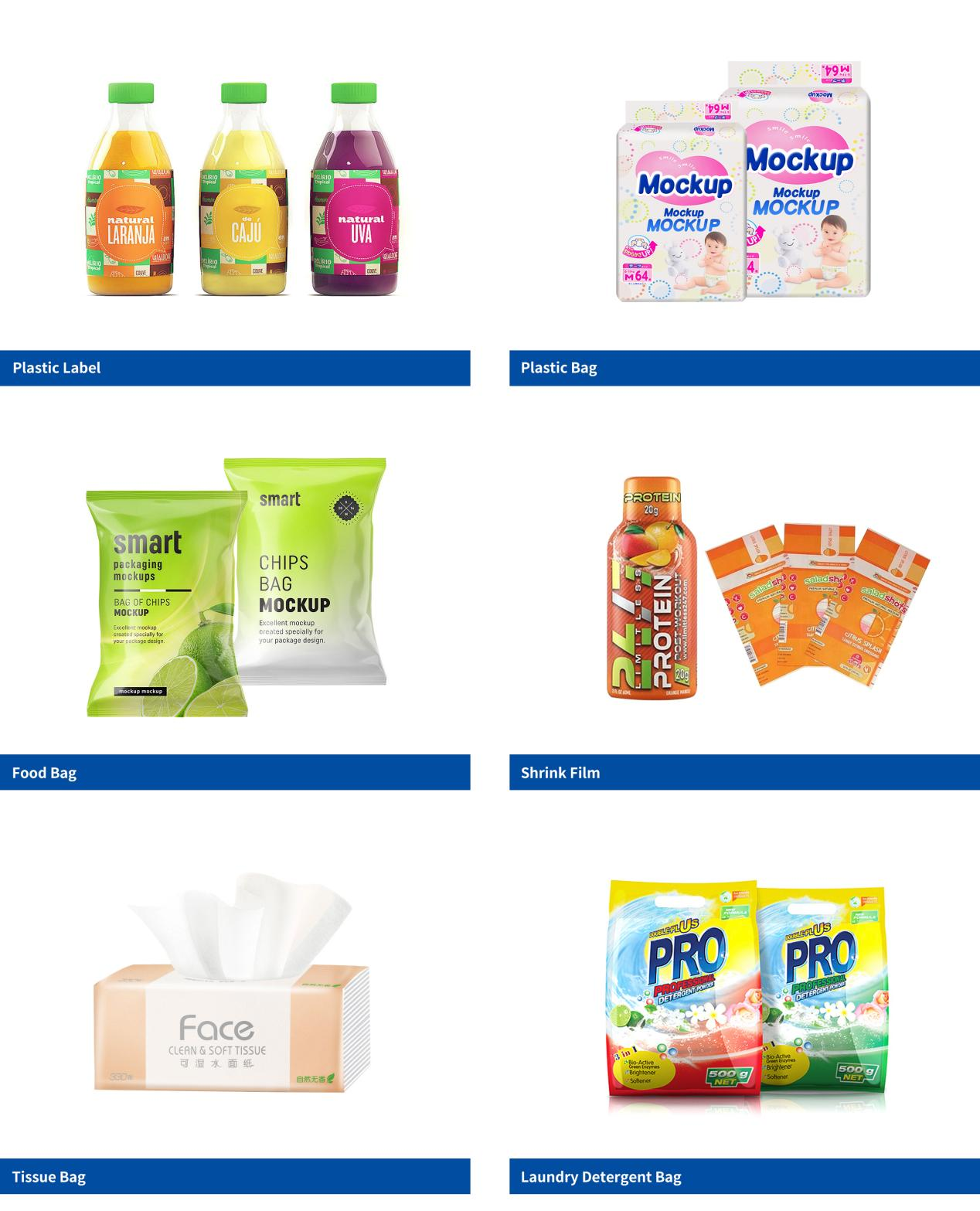

The polyethylene flexographic graphic printing machine is a crucial tool in the food printing and packaging industry, as it allows designs and texts to be printed directly onto polyethylene materials and other flexible substrates.

1. High production capacity: The flexographic printing machine can print continuously at a very high speed, making it ideal for high production volumes.

2. Excellent printing quality: This machine uses special inks and flexible printing plates that allow for exceptional printing quality and excellent color reproduction.

3. Printing flexibility: The printing flexibility allows the machine to print on different types of flexible substrates, including polyethylene, paper, cardboard, and others.

4. Ink saving: The ink dampening technology of the flexographic printing machine allows for efficient use of ink, which in turn reduces costs in production.

5. Easy Maintenance: The flexographic printing machine is easy to maintain thanks to its accessible components and advanced technology.

●Detailed image

Post time: Nov-02-2024