The 4 color ci flexo printing machine is centered on the central impression cylinder and has a multi-color group surround layout to ensure zero-stretching material transmission and achieve ultra-high overprint accuracy. It is specially designed for easily deformed substrates such as films and aluminum foils, has a fast and stable printing speed, and combines environmentally friendly inks with intelligent control systems, taking into account both efficient production and green needs. It is an innovative solution in the field of high-precision packaging.

●Technical Parameters

|

Model |

CHCI6-600J-S |

CHCI6-800J-S |

CHCI6-1000J-S |

CHCI6-1200J-S |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

250m/min |

|||

|

Max. Printing Speed |

200m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1000mm/Φ1200mm |

|||

|

Drive Type |

Central drum with Gear drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

●Machine Features

1.Ci flexo printing machine are particularly advanced and efficient presses that offer a wide range of benefits to companies in the packaging industry. With its high-speed functionality and superior print quality, the machine is capable of producing crisp and vivid prints on various types of packaging materials

2.One of the main advantages of using a Ci flexo printing machine is that all print groups are arranged radially around a single central impression cylinder, with the material being transported along the cylinder throughout, eliminating stretching deformation caused by multi-unit transfers, ensuring precise and accurate printing, and high-quality prints every time.

3.The cI flexo press is also cost-effective and environmentally friendly. The machine requires minimal maintenance and operational setup, which reduces downtime and increases productivity. In addition, it uses water-based inks and environmentally friendly materials, meets food-grade packaging safety standards and can help companies reduce their carbon footprint. It is a benchmark for technological innovation in the fields of food, medicine, and environmentally friendly packaging.

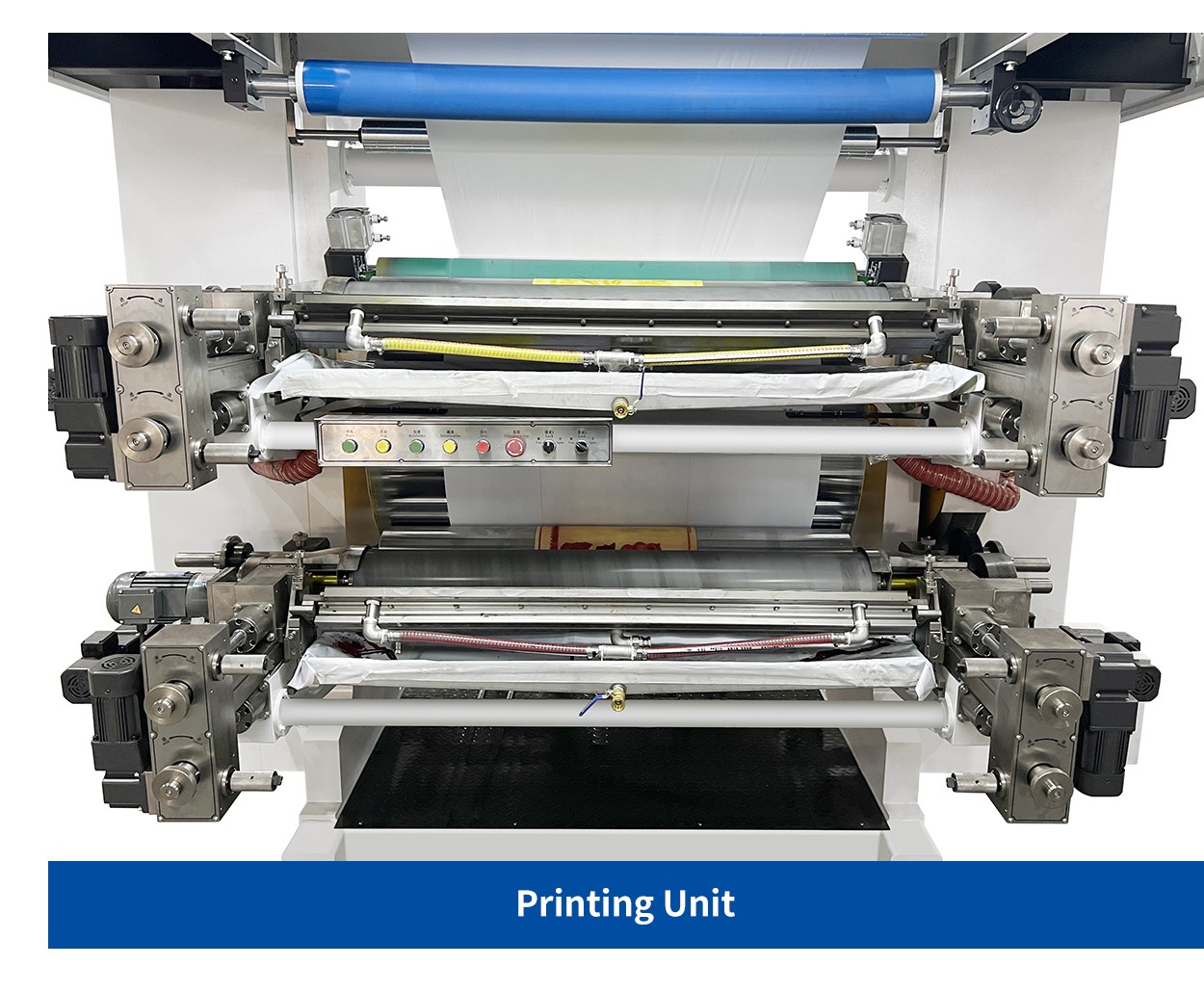

●Details Dispaly

●Printing sample

Post time: Mar-06-2025