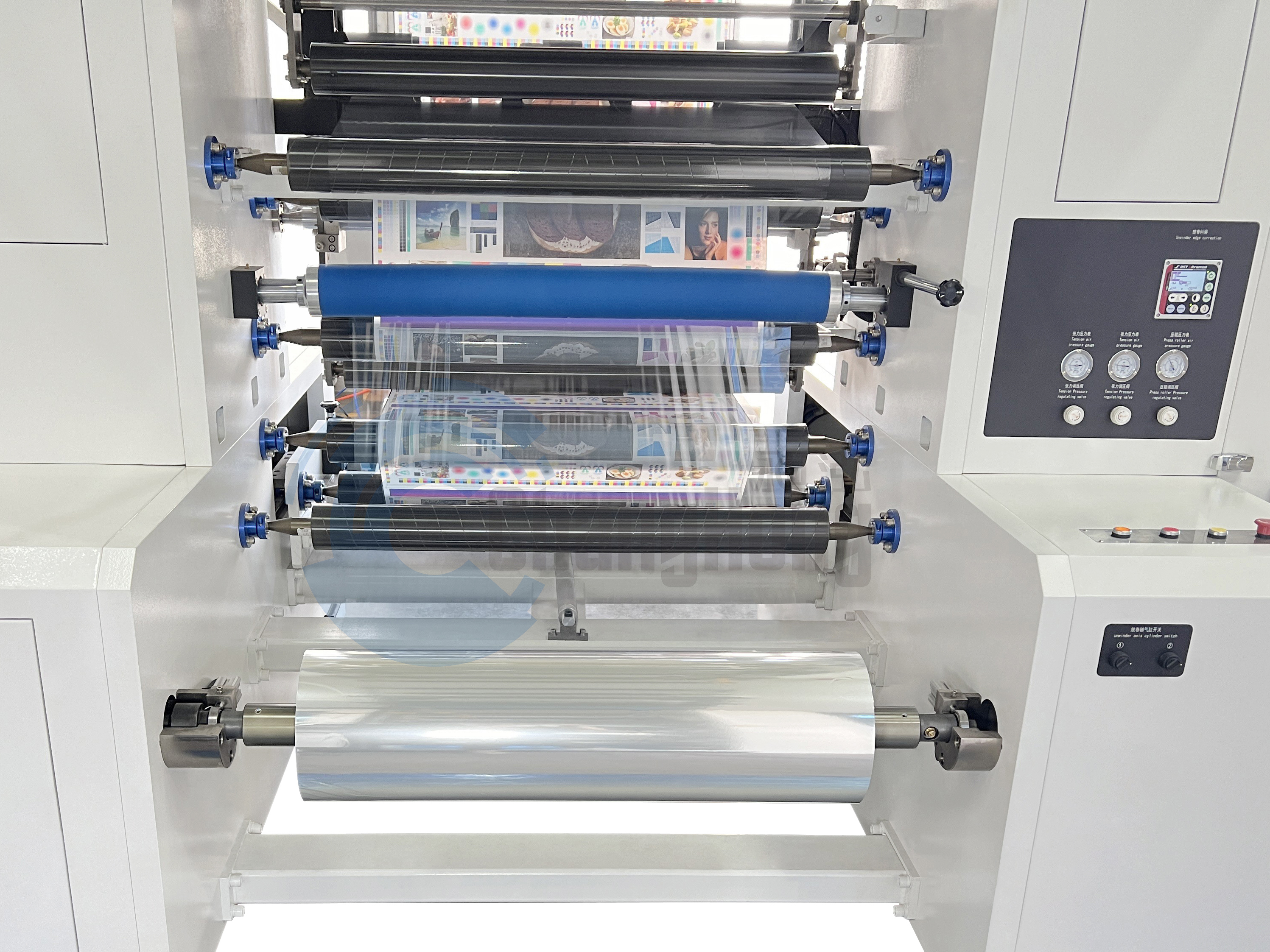

The flexographic printer is a highly versatile and efficient machine for high-quality, high-volume printing on paper, plastic, cardboard and other materials. It is used worldwide for the production of labels, boxes, bags, packaging and much more.

One of the main advantages of the flexographic printer is its ability to print on a wide range of substrates and inks, allowing for the production of high-quality products with intense, sharp colours. In addition, this machine is highly adaptable and can be used in a wide variety of configurations to suit individual production needs.

●Technical Specifications

| Model | CHCI8-600F-S | CHCI8-800F-S | CHCI8-1000F-S | CHCI8-1200F-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 500m/min | |||

| Max. Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1200mm | |||

| Drive Type | Gearless full servo drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 400mm-800mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, Breathable Film | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

●Video Introduction

●Machine Features

Gearless flexographic press is a high-quality and precision printing tool used in the printing and packaging industry. Some of its key features include:

1. Higher printing speed: The gearless flexographic press is capable of printing at a much higher speed than conventional flexographic presses.

2. Lower production cost: Due to its modern, gearless version, it allows for savings in production and maintenance costs.

3. Higher print quality: The gearless flexographic press produces exceptional print quality compared to other types of printers.

4. Ability to print on various substrates: The gearless flexographic press can print on various materials including paper, plastic, cardboard, among others.

5. Reduction of printing errors: It uses various automated tools such as print readers and quality inspection capable of identifying and correcting errors in printing.

6. Environmentally friendly technology: This modern version promotes the use of water-based inks, which are more environmentally friendly than traditional conventional systems that use solvent-based inks.

●Details Dispaly

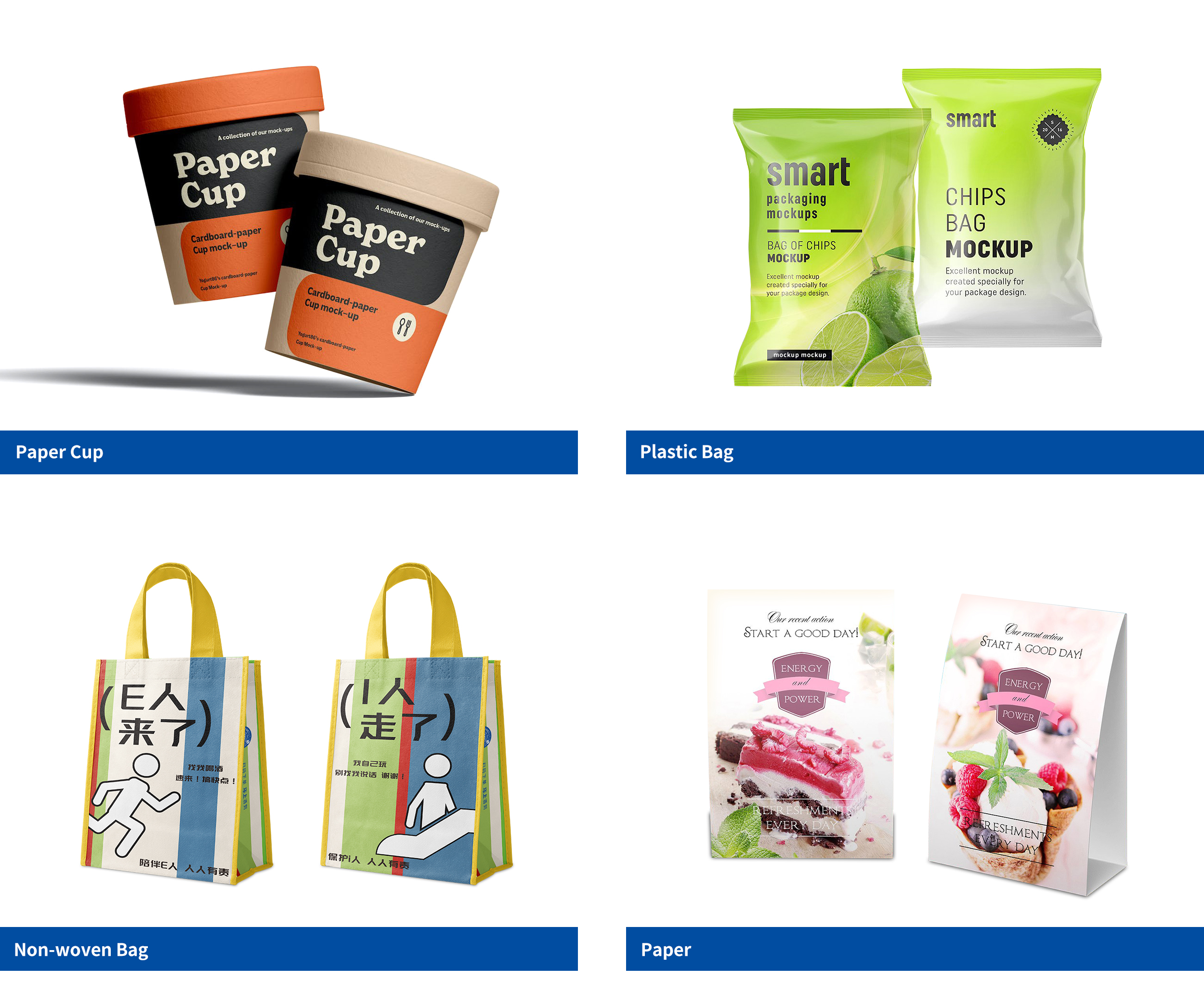

●Printing samples

Post time: Aug-09-2024