Full servo ci flexo press for nonwoven/paper cup/paper

Full servo ci flexo press for nonwoven/paper cup/paper

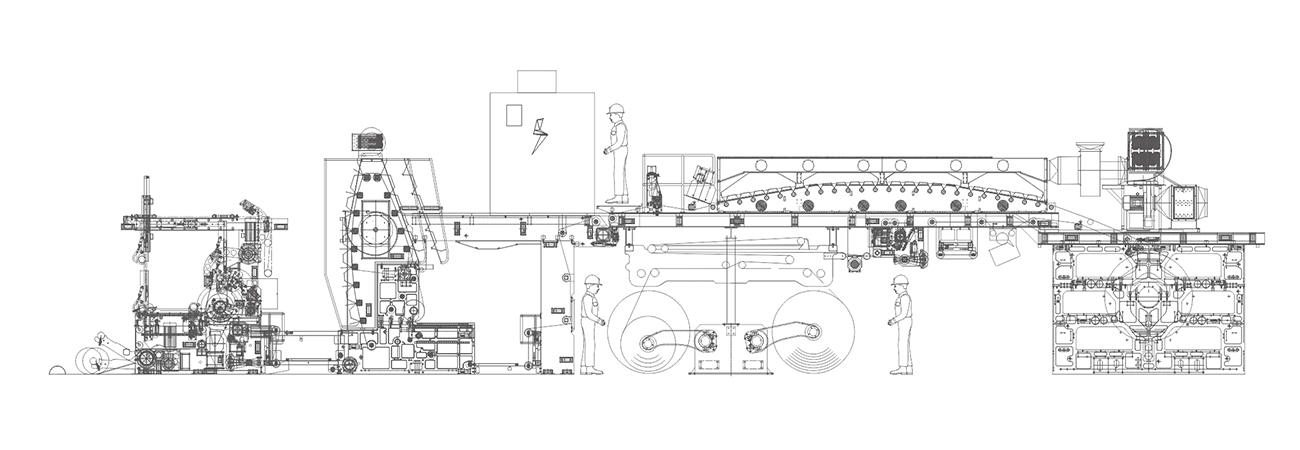

Material Feeding Diagram

Technical Specifications

|

Model |

CHCI6-1300F-Z |

|

Max. Web Width |

1300mm |

|

Max.Printing Width |

1270mm |

|

Max. Mechanical Speed |

500m/min |

| Max.Printing Speed | 450m/min |

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1200mm/Φ1500mm |

| Drive Type | Gearless full servo drive |

|

Photopolymer Plate |

To be specified |

|

Ink |

Water base ink or solvent ink |

|

Printing Length (repeat) |

400mm-800mm |

| Range Of Substrates |

Non woven、Paper、Paper Cup |

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified |

Video Introduction

Machine Features

Gearless flexo printing presses offer a range of advantages over traditional gear-driven presses, including:

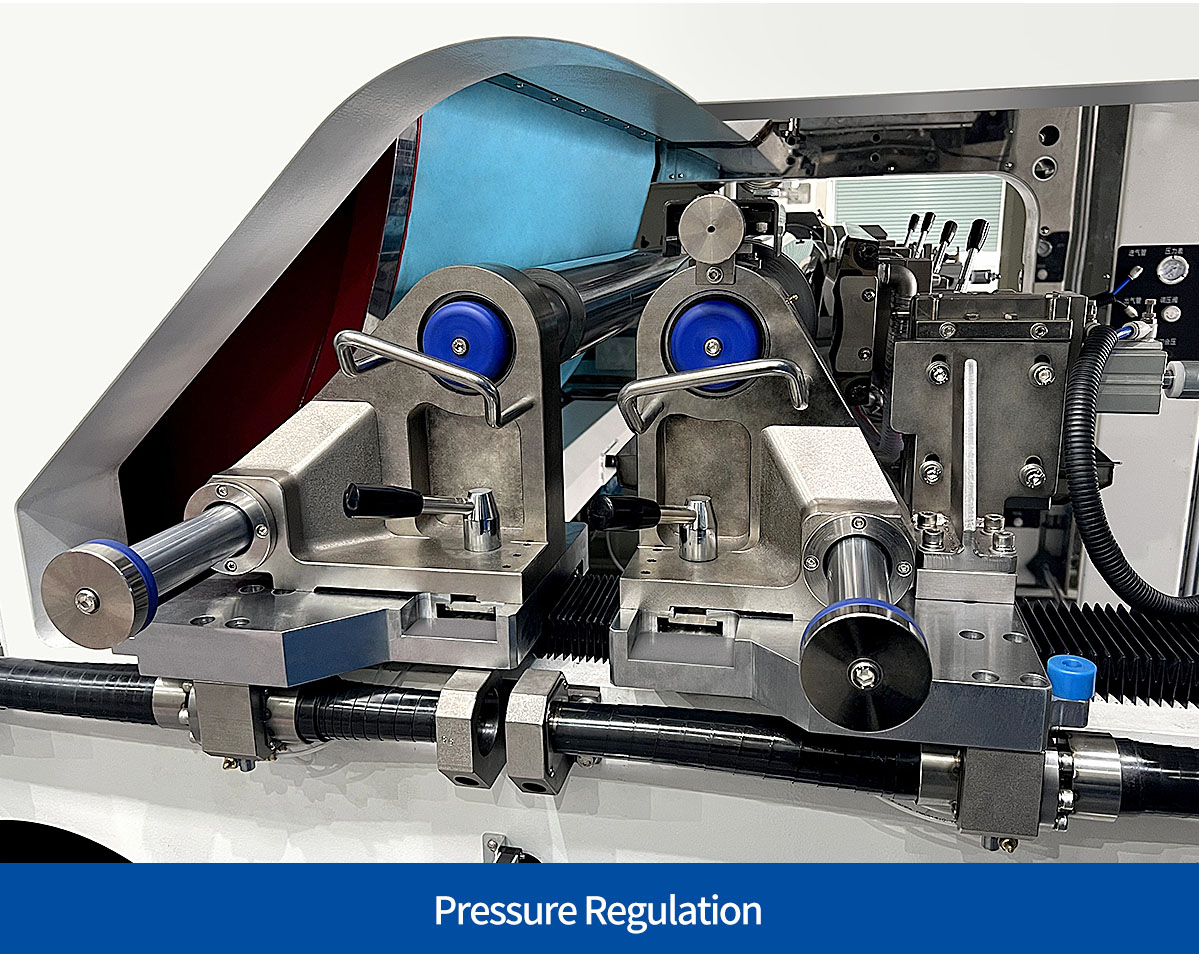

- Increased registration accuracy due to lack of physical gears, which eliminates the need for constant adjustment.

- Lower production costs since there are no gears to adjust and fewer parts to maintain.

- Variable web widths can be accommodated without the need to manually change gears.

- Larger web widths can be achieved without compromising print quality.

- Increased flexibility as digital plates can easily be exchanged without the need to reset the press.

- Faster print speeds as the flexibility of digital plates allows for faster cycles.

- Higher quality print results due to improved registration accuracy and digital imaging capabilities.

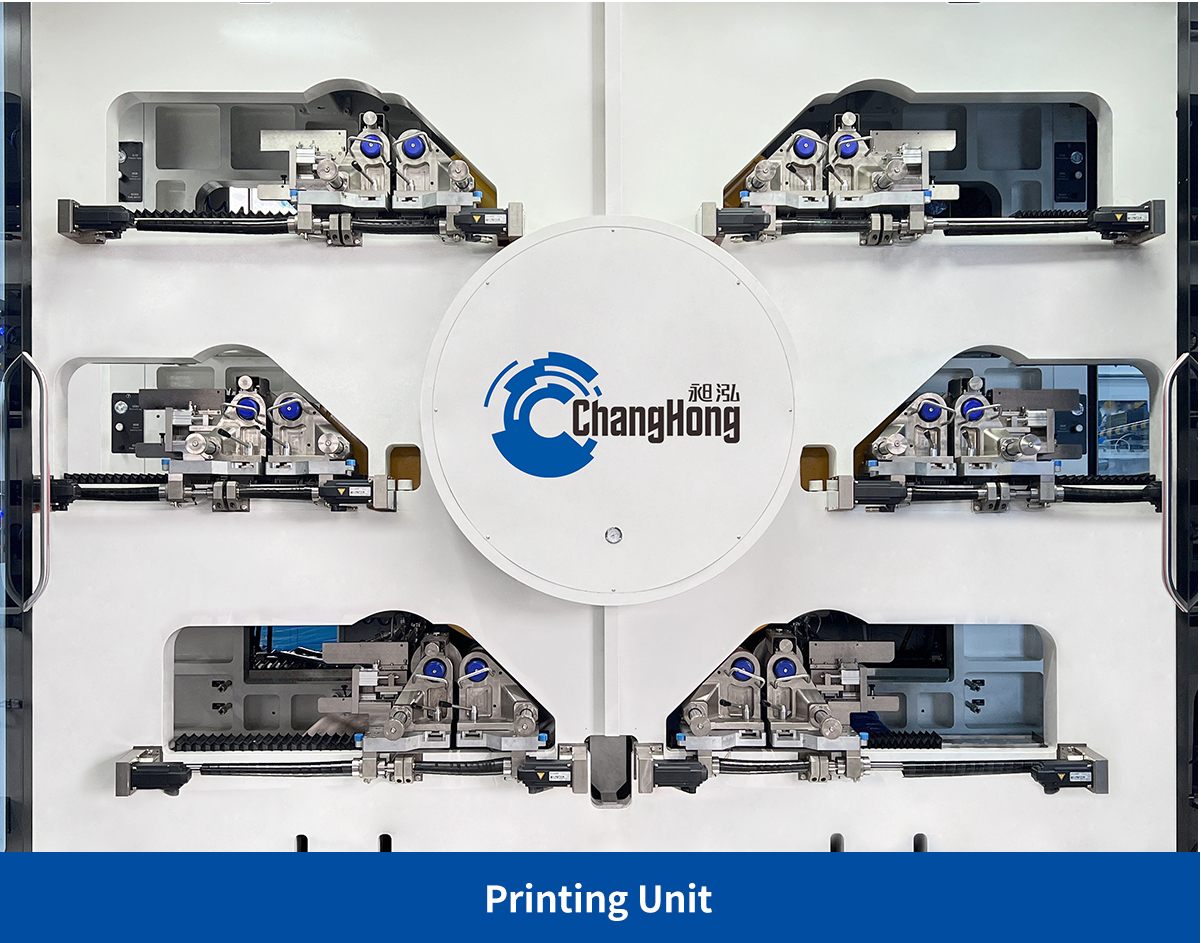

Details Dispaly

Printing samples

FAQ

Q: What is a gearless flexo printing press?

A: A gearless flexo printing press is a type of printing machine that prints high-quality images on various substrates, such as paper, film, and corrugated cardboard. It uses flexible printing plates to transfer ink to the substrate, which results in a vibrant and sharp print.

Q: How does a gearless flexo printing press work?

A: In a gearless flexo printing press, the printing plates are mounted onto sleeves that are attached to the printing cylinder. The printing cylinder rotates at a consistent speed, while the flexible printing plates are stretched and mounted onto the sleeve for precise and repeatable printing. Ink is transferred to the plates and then onto the substrate as it passes through the press.

Q: What are the advantages of a gearless flexo printing press?

A:One advantage of a gearless flexo printing press is its ability to produce large quantities of high-quality prints quickly and efficiently. It also requires less maintenance because it does not have traditional gears that can wear down over time. Additionally, the press can handle a wide range of substrates and ink types, making it a versatile option for printing companies.