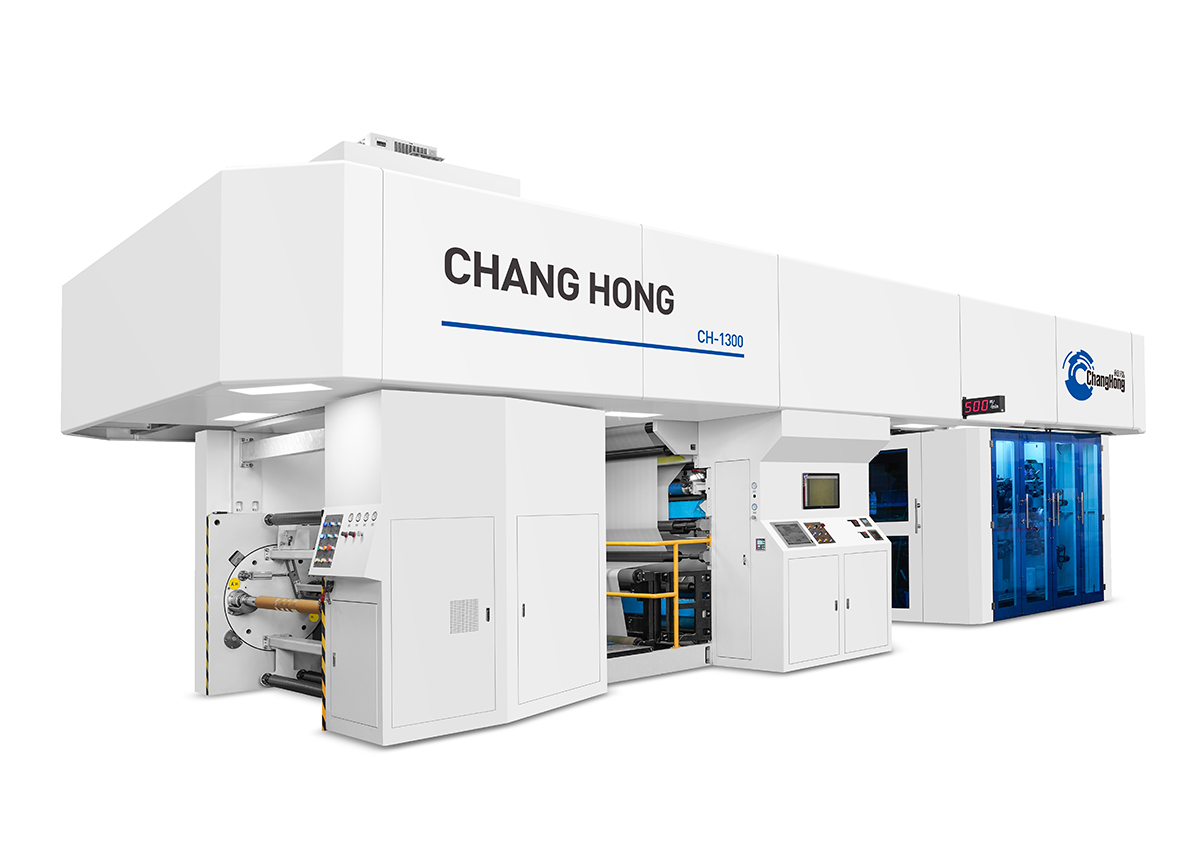

Factory wholesale Flexographic Aluminum Foil Plastic Paper Cup Film Label Roll Cold Stamping Laminating Die Cutting Punching Slitting Color Flexo Printing Machine

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Factory wholesale Flexographic Aluminum Foil Plastic Paper Cup Film Label Roll Cold Stamping Laminating Die Cutting Punching Slitting Color Flexo Printing Machine, we could solve our customer problems asap and do the profit for our customer. For those who need superior provider and excellent , pls choose us , thanks !

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Die Cutting Punching Machine and Stamping Machine, Our product quality is one of the major concerns and has been produced to meet the customer’s standards. “Customer services and relationship” is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

●Technical Specifications

| Model | CHCI4-600F | CHCI4-800F | CHCI4-1000F | CHCI4-1200F |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 520mm | 720mm | 920mm | 1120mm |

| Max. Machine Speed | 500m/min | |||

| Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gearless full servo drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-800mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

●Video Introduction

●Function Description

● Double station unwinding

● Full servo Printing system

● Pre registration function

● Production menu memory function

● Start up and shut down automatic clutch pressure function

● Automatic pressure adjustment function in the process of printing speed up

● Chamber doctor blade quantitative ink supply system

● Temperature control and centralized drying after printing

● EPC before printing

● It has cooling function after printing

● Double station winding.

Details Dispaly

Turret rolling system double location: Tension control Using ultra-light floating roller control, automatic tension compensation, closed loop control (low friction cylinder position Detection, precise pressure regulating valve control, automatic alarm or shutdown when the roll diameter reaches the set value)

The pressure between the anilox roller and the printing plate roller is driven by 2 servo motors for each color, and the pressure is adjusted by ball screws and upper and lower double linear guides, with position memory function

Intelligent continuous constant temperature control, fully enclosed structure, air box adopts heat preservation structure.

Check the printing quality on the video screen.

Printing samples

Packaging and Delivery

●FAQ

Q: Are you a factory or trading company?

A: We are a factory, the real manufacturer not trader.

Q: Where is your factory and how can I visit it?

A: Our factory is located in fuding City, fujian Province, China about 40 minutes by plane from Shanghai ( 5 hours by train)

Q: What is your after-sale service?

A: We have been in flexo printing machine business for many years, we will send our professional engineer to install and test machine.

Beside, we can also provide online support, video technical support, matching parts delivery, etc. So our after-sales services is always reliable.

Q: How to get machines price?

A: Pls provide following information:

1)The color number of printing machine;

2)Material width and effective print width;

3)What material to print;

4)The photo of printing sample.

Q: What services do you have?

A: 1 Year Guarantee !

100% Good Quality !

24 Hours online Service!

The buyer paid tickets ( go and back to FuJian), and pay 150usd/day during the install and testing period!

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Factory wholesale Flexographic Aluminum Foil Plastic Paper Cup Film Label Roll Cold Stamping Laminating Die Cutting Punching Slitting Color Flexo Printing Machine, we could solve our customer problems asap and do the profit for our customer. For those who need superior provider and excellent , pls choose us , thanks !

Factory wholesale Die Cutting Punching Machine and Stamping Machine, Our product quality is one of the major concerns and has been produced to meet the customer’s standards. “Customer services and relationship” is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.