Factory Price Flexographic Printing Products - 4 colour CI flexo printing machine for plastic paper – Changhong

Factory Price Flexographic Printing Products - 4 colour CI flexo printing machine for plastic paper – Changhong Detail:

Characteristic

- The machine introduction & absorption of European technology / process manufacturing, supporting / full functional.

- After mounting the plate and registration, no longer need registration, improve yield.

- Replacing 1 set of Plate Roller (unloaded old roller, installed six new roller after tightening), only 20 Minute registration can be done by printing.

- The machine first mount plate, pre-trapping function, to be completed in advance prepress trapping in the shortest possible time.

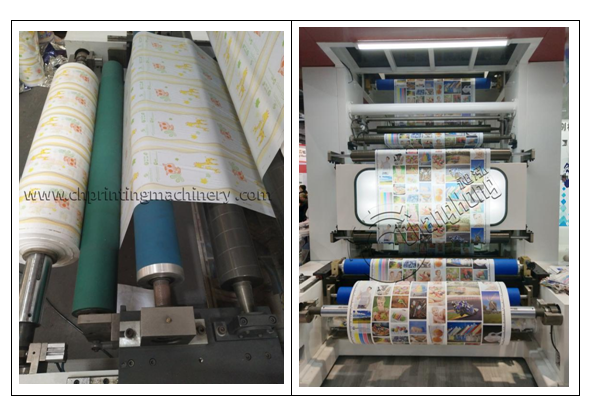

- Maximum production machine speed up 200m/min, registration accuracy ±0.10mm.

- The overlay accuracy does not change during lifting running speed up or down.

- When machine stop, Tension can be maintained, the substrate is not deviation shift.

- The whole production line from the reel to put the finished product to achieve non-stop continuous production, maximize product yield.

- With precision structural, easy operation, easy maintenance, high degree of automation and so on, only one person can operate.

technical specifications

| Model | CHCI4-600E | CHCI4-800E | CHCI4-1000E | CHCI4-1200E |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 300m/min | |||

| Printing Speed | 250m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Unwinder unit

Single unwind central drive , with servo motor ,Inverter control Closed-loop.

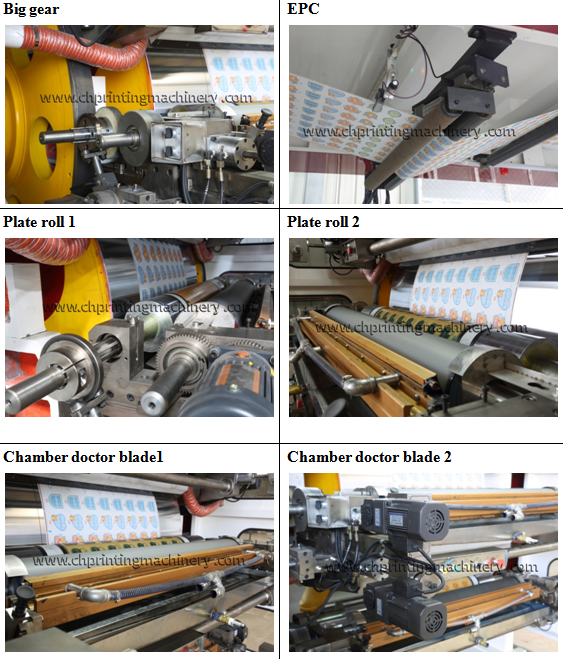

Printing Unit

- Color: 4 Color

- Drive mode: Gear Drive

- Drive motor : Servo Motor drive ; Inverter control close loop control

- Printing way : 1)Plate -Photopolymer plate ; 2)Ink–water base or solvent ink

- Printing Repeat: 400-900mm

- Gearing of printing cylinder: 5mm

Doctor blade

- Chamber blade 4 pcs

- Both way blade aluminium alloy ink box.

- Closed ink tank(original import use life 30-60days).

- Blade open and close by manual (Safety).

- Equipped with doctor chamber for fast change.

- It is made from Aluminum alloy and closed type to reduce solvent volatilization and keep the ink in good viscosity and clean.

- There is forward and reverse directions doctor inside the chamber. The reverse doctor is for sealing the chamber and the forward doctor is for scratching the ink.

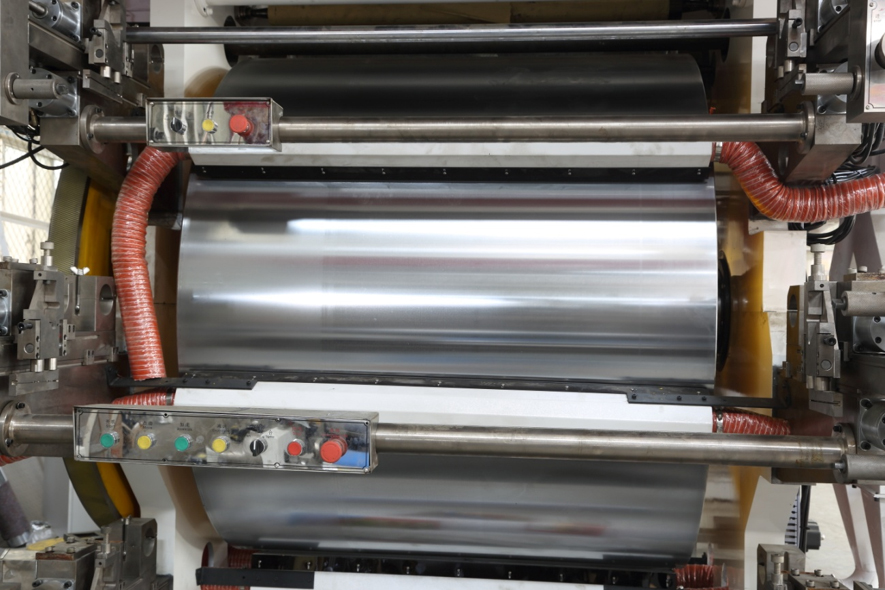

Big Central Drum

- Surface of central press roller with constant temperature.

- ±0.008mm

- Diameter: Ф1200mm

- Made in China

Dryer between each color

- Electrical heating, transformed into circulating air heating by heat exchanger. Temperature control adopts intelligent temperature control, contactless solid-state relay, set 2 control, suit to different technology、environment production, save energy consumption, enforce PID temperature control and temperature control precision,±2℃.

Drying system

- Hot air mode:Electrical heating, transformed into circulating air heating by heat exchanger. Temperature control adopts intelligent temperature control, contactless solid-state relay, set 2 control, suit to different technology、environment production, save energy consumption, enforce PID temperature control and temperature control precision,±2℃.

Drying oven structure

- Drying oven inner container.

Single rewind

- One unit use center drive rewind,servo motor ,Inverter closed-loop control.

Image static monitoring system

- Display resolution: 1280*1024

- Enlargement factor: 3-30(Enlargement factor of area)

Printing Samples

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for Factory Price Flexographic Printing Products - 4 colour CI flexo printing machine for plastic paper – Changhong , The product will supply to all over the world, such as: Comoros, Macedonia, Rio de Janeiro, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

Write your message here and send it to us