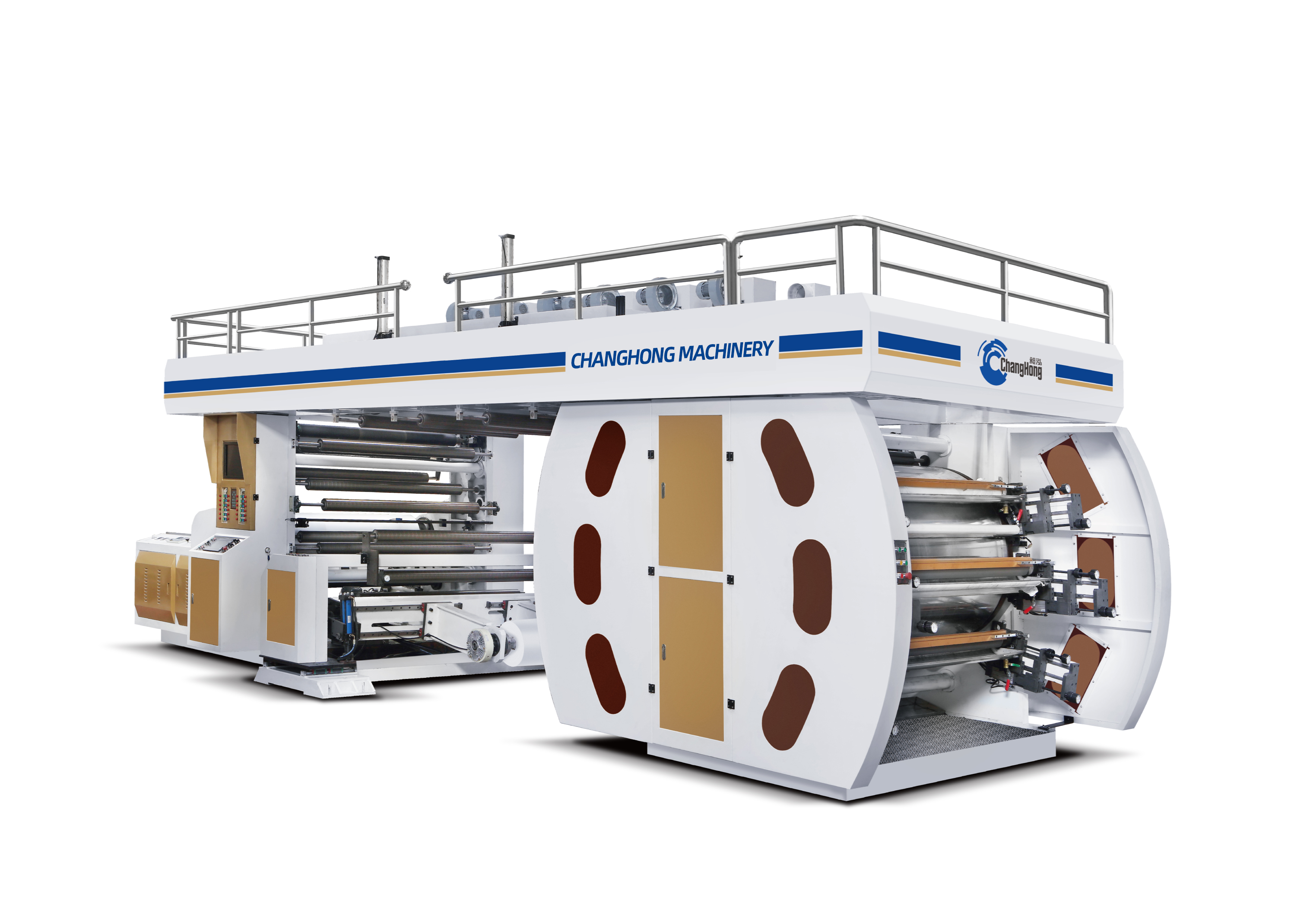

CI Flexo Printing Machine

Central Drum 8 Color Ci Flexo Machine

CI Flexo Printing Machine is a popular high-performance printing machine designed specifically for printing on flexible substrates. It is characterized by high-precision registration and high-speed production. It is mainly used for printing on flexible materials such as paper, film and plastic film. The machine can produce a wide range of printing such as flexo printing process, flexo label printing etc. It is widely used in the printing and packaging industry.

SHAFTLESS UNWINDING 6 COLOR CI FLEXOGRAPHIC PRINTING MACHINERY/CENTRAL IMPRESSION FLEXO PRESS FOR PAPER CUP/PAPER BAG

This Shaftless Unwinding 6 color ci flexographic printing machine is specifically designed for high-efficiency printing of paper cups, paper bags, and other packaging products. It incorporates advanced central impression cylinder technology and a shaftless unwinding system to achieve high-precision register, stable tension control, and quick plate changes. It meets the stringent demands of industries such as food packaging and daily-use paper products for high color reproduction accuracy and precise register.

FFS HEAVY-DUTY FILM FLEXO PRINTING MACHINE

One of the key features of the FFS Heavy-Duty Film Flexo Printing Machine is its ability to print on heavy-duty film materials with ease. This printer is designed to handle high-density polyethylene (HDPE) and low-density polyethylene (LDPE) film materials, ensuring that you get the best printing results on any material that you choose.

6 color central drum ci Flexo Printing Machine for PE/PP/ PET/PVC

This ci flexo printing machine is specially designed for film printing. It adopts central imprinting technology and intelligent control system to achieve precise overprinting and stable output at high speed, helping to upgrade the flexible packaging industry.

6 colors Double sided printing central drum CI flexo printing machine

Double-sided printing is one of the main features of this machine. This means that both sides of the substrate can be printed simultaneously, allowing for greater production efficiency and a reduction in production costs. In addition, the machine features a drying system that ensures that the ink dries quickly to prevent smearing and ensure crisp, clear printing.

Paper Cup Ci Flexo Printing Machine

The Paper Cup Flexo Printing Machine is a specialized printing equipment used for printing high-quality designs on paper cups. It uses the Flexographic printing technology, which involves the use of flexible relief plates to transfer ink onto the cups. This machine is designed to provide excellent printing results with high printing speed, precision, and accuracy. It is suitable for printing on different types of paper cups

HIGH SPEED CI FLEXO PRESS FOR LABEL FILM

CI Flexo Press is designed to work with a wide range of label films, ensuring flexibility and versatility in operations. It utilizes a Central Impression (CI) drum which enables the printing of wide and labels with ease. The press is also fitted with advanced features such as auto-register control, automatic ink viscosity control, and an electronic tension control system that ensures high-quality, consistent print results.

CI flexo printing machine roll to roll type

CI Flexo is a type of printing technology used for flexible packaging materials. It is an abbreviation for “Central Impression Flexographic Printing.” This process uses a flexible printing plate mounted around a central cylinder to transfer ink to the substrate. The substrate is fed through the press, and the ink is applied to it one color at a time, allowing for high-quality printing. CI Flexo is often used for printing on materials such as plastic films, paper, and foil, and is commonly used in the food packaging industry.

6+6 Color CI Flexo machine For PP Woven Bag

6+6 color CI flexo machines are printing machines used mainly for printing on plastic bags, such as PP woven bags commonly used in the packaging industry. These machines have the capacity to print up to six colors on each side of the bag, hence 6+6. They use a flexographic printing process, where a flexible printing plate is used to transfer ink onto the bag material. This printing process is known for being fast and cost-effective, making it an ideal solution for large-scale printing projects.

Medium width Gearless CI flexographic printing machine 500m/min

The system eliminates the need for gears and reduces the risk of gear wear, friction and backlash.The Gearless CI flexographic printing machine minimizes waste and environmental impact. It uses water-based inks and other environmentally friendly materials, reducing the carbon footprint of the printing process. It features an automatic cleaning system that reduces the time and effort required for maintenance.

6 COLOUR GEARLESS CI FLEXO PRINTING PRESS

The mechanics of a gearless flexo press replace the gears found in a conventional flexo press with an advanced servo system that provides more precise control over printing speeds and pressure. Because this type of printing press requires no gears, it provides more efficient and accurate printing than conventional flexo presses, with fewer maintenance costs associated

8 Color CI Flexo Machine for PP/PE/BOPP

CI Flexo Machine inked impression is achieved by pressing a rubber or polymer relief plate against the substrate, which is then rolled across the cylinder. Flexographic printing is widely used in the packaging industry due to its speed and high-quality results.