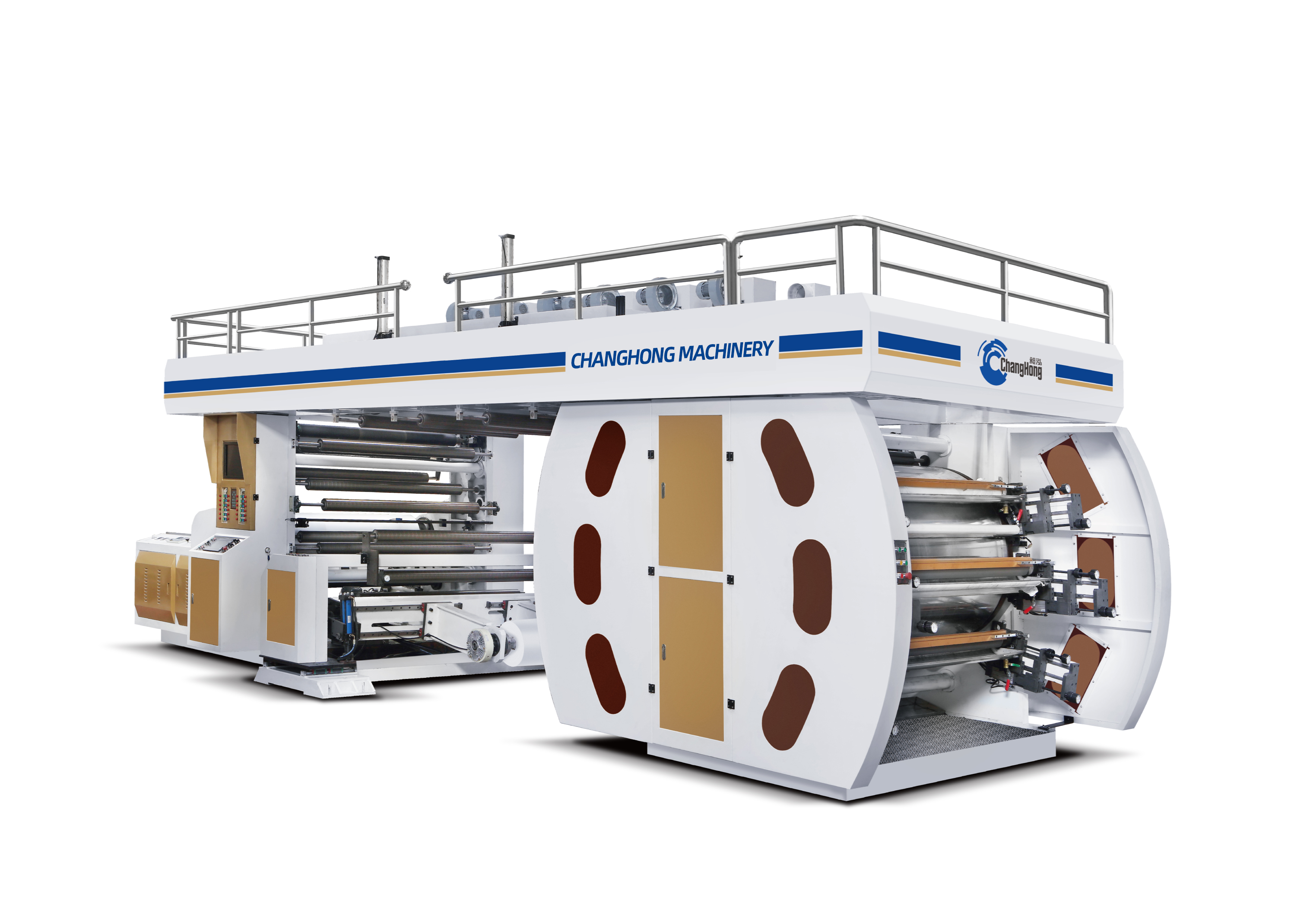

China OEM Changhong Paper Bag Ci Flexographic Printing Machine Central Drum 4 6 8 Color Flexo Presses

We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for China OEM Changhong Paper Bag Ci Flexographic Printing Machine Central Drum 4 6 8 Color Flexo Presses, For more information and facts, you should never wait to make contact with us. All inquiries from you may be highly appreciated.

We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for Central Drum flexo press and Ci Flexo Printer, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Technical Specifications

| Model | CHCI4-600J | CHCI4-800J | CHCI4-1000J | CHCI4-1200J |

| Max. Web Value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Value | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gear drive | |||

| Plate Thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High precision printing: Paper cup flexo printing machine can produce high-quality prints with a high level of precision.

3. Low maintenance cost: The machine is designed to require low maintenance. It has an easy-to-maintain structure.

5. Versatile: The machine is versatile and can print on various types of materials to produce different types of paper cups.

6. Automatic registration control: The machine has an automatic registration control system, which ensures accurate printing on the paper cups.

7. Cost-effective: The Paper cup flexo printing machine is a cost-effective production tool, and it can help increase the profitability of paper cup production.

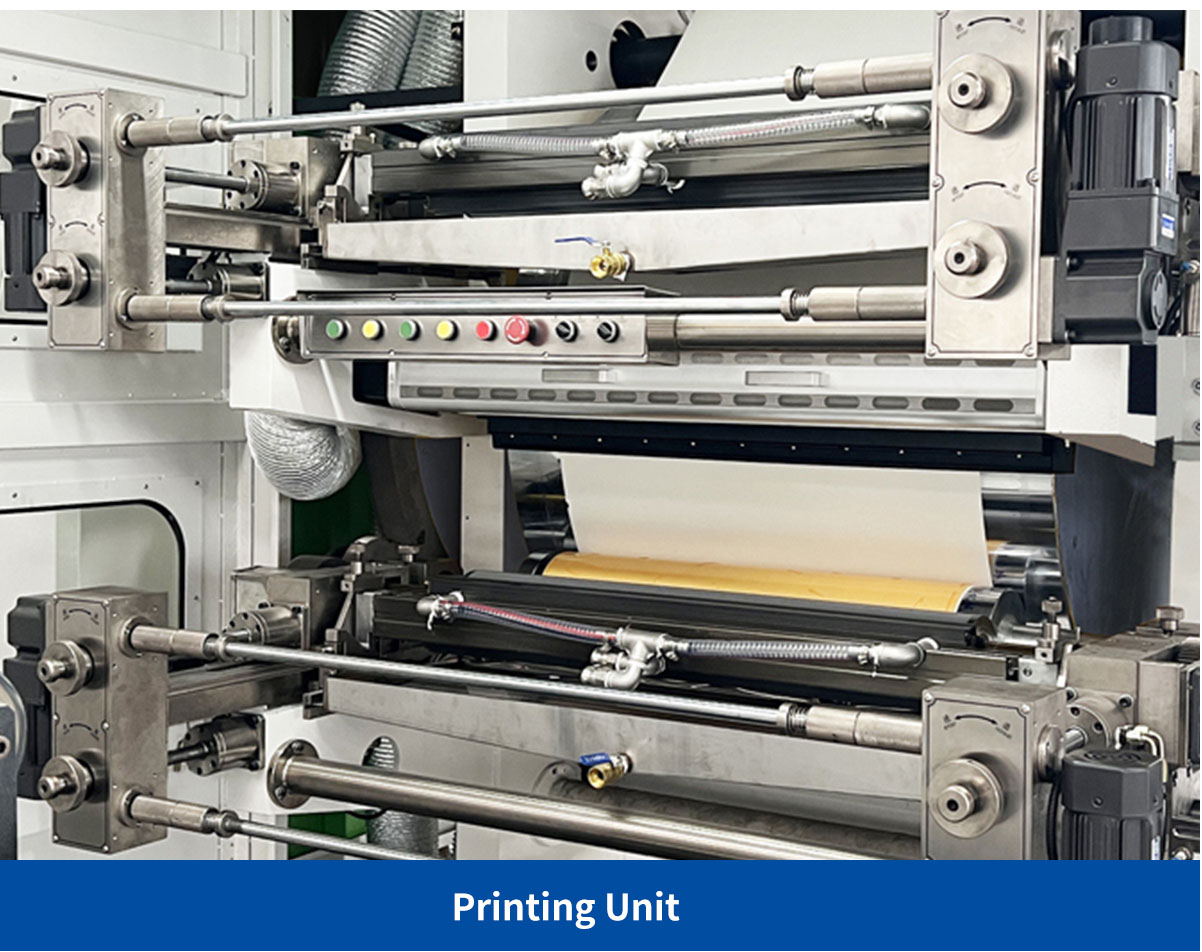

Details Dispaly

Printing samples

FAQ

Q: What is a paper cup CI flexo printing machine?

A: paper cup CI flexo printing machine is designed for the high-speed printing of various sizes and styles of paper cups and materials. It uses a continuous ink supply system to ensure accurate and consistent printing quality across large quantities of cups.

Q: How does a paper cup CI flexo printing machine work?

A:The machine operates using a rotating cylinder that transfers ink to the cup material as it moves through the machine. The cups are fed into the machine and passed through the ink application and curing process before being ejected and collected for further processing.

Q: What types of ink are used in a paper cup C.I. flexo printing machine?

A:Different types of inks can be used in a paper cup CI flexo printing machine, depending on the cup material used and the design requirements. Common types of inks used include water-based inks, UV-curable inks, and solvent-based inks.

We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for China OEM Changhong Paper Bag Ci Flexographic Printing Machine Central Drum 4 6 8 Color Flexo Presses, For more information and facts, you should never wait to make contact with us. All inquiries from you may be highly appreciated.

China OEM Central Drum flexo press and Ci Flexo Printer, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.