4+4 Color CI Flexo machine For PP Woven Bag

Technical Specifications

| Model | CHCI-600T | CHCI-800T | CHCI-1000T | CHCI-1200T |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 500mm | 700mm | 900mm | 1100mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ1500mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 500mm-1100mm | |||

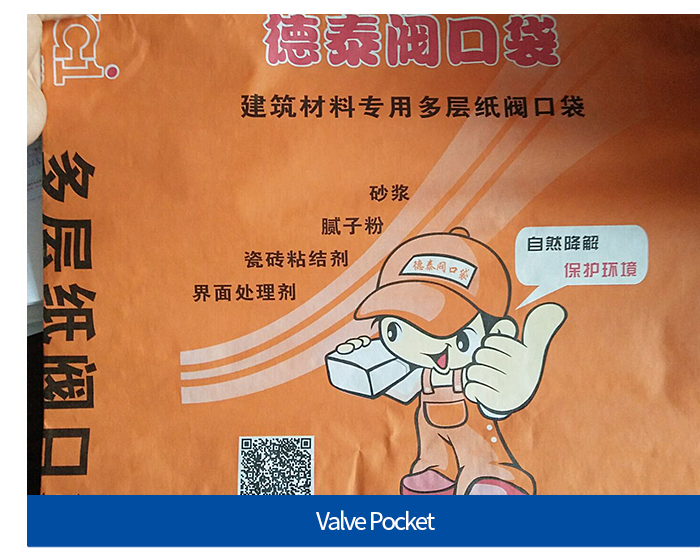

| Range Of Substrates | PP Woven Bags, Paper-Plastic Bags, Valve Bags | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Characteristic

● The machine introduction & absorption of European technology / process manufacturing, supporting / full functional.

● After mounting the plate and registration, no longer need registration, improve yield.

● Replacing 1 set of Plate Roller (unloaded old roller, installed six new roller after tightening), only 20 Minute registration can be done by printing.

● The machine first mount plate, pre-trapping function, to be completed in advance prepress trapping in the shortest possible time.

● Maximum production machine speed up 200m/min, registration accuracy ±0.10mm.

● The overlay accuracy does not change during lifting running speed up or down.

● When machine stop, Tension can be maintained, the substrate is not deviation shift.

● The whole production line from the reel to put the finished product to achieve non-stop continuous production, maximize product yield.

● With precision structural, easy operation, easy maintenance, high degree of automation and so on, only one person can operate.

Details Dispaly

1,Center-driven unwinding, equipped with magnetic powder brake, equipped with automatic tension control;

2,Tension control: Ultra-light floating roller control, automatic tension compensation,closed loop control;

3,It has the function of automatic shutdown when the material is interrupted, and the tension maintains the function to avoid the substrate slack and deviation during the shutdown

4, Configure automatic EPC system before printing EPC: Before printing, a four-roller automatic EPC ultrasonic probe correction system has manual/automatic/center return functions, and the left and right translation can be adjusted by ±65mm.

1,Type : CI Flex Printing Machine

2,Color: 4 colors on the front + 4 colors on the back

3,Drive mode: Servo gear drive

4,Motor: Servo motor drive, inverter control closed loop control

5,Printing method :Photosensitive resin plate, suitable for both water-based and alcohol-soluble inks

6,Printing Repeat: 400-1200mm

1,Check range: depends on the material width, arbitrarily setting. It is ok for adjustable point monitor or automatic back and forth.

1,Double-station Surface friction winding, Equipped with servo cutter, stable segment length

2,The tension control adopts ultra-light floating roller control, automatic tension compensation, closed-loop control, and arbitrary setting of taper tension (low-friction cylinder position detection, precision pressure regulator control, automatic alarm or shutdown when the roll diameter reaches the set value)

Printing Samples

FAQ

Q: Are you a factory or trading company?

A: We are a factory, the real manufacturer not trader.

Q: Where is your factory and how can I visit it?

A: Our factory is located in fuding City, FuJian Province, China about 40 minutes by plane from Shanghai ( 5 hours by train)

Q: What is your after-sale service?

A: We have been in flexo printing machine business for many years, we will send our professional engineer to install and test machine.

Beside, we can also provide online support, video technical support, matching parts delivery, etc. So our after-sales services is always reliable.

Q: How to get machines price?

A: Pls provide following information:

1)The color number of printing machine;

2)Material width and effective print width;

3)What material to print;

4)The photo of printing sample.

Q: What services do you have?

A: 1 Year Guarantee !

100% Good Quality !

24 Hours online Service!

The buyer paid tickets ( go and back to FuJian), and pay 150usd/day during the install and testing period!