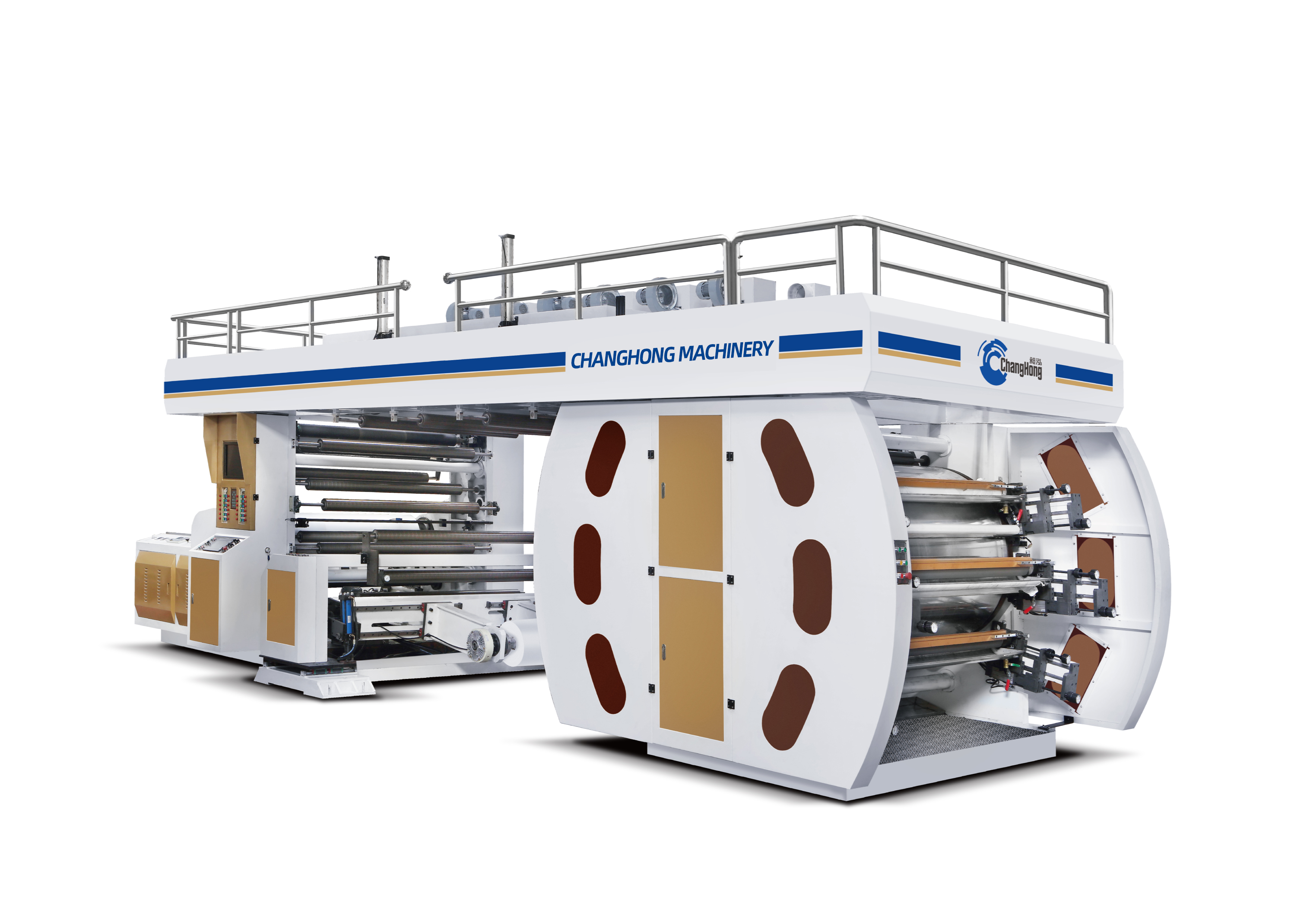

6 Colour Stack Flexo Printing Machine

technical specifications

| Model | CH6-600B-S | CH6-800B-S | CH6-1000B-S | CH6-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE,HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

● Machine form: High precision gear transmission system,Use big gear drive and register the color more accurate.

● The structure is compact. The parts of the machine can interchange standardization and easy to get. And we chooser low abrasion design.

● The plate is really simple. It can save more time and cost less.

● The printing pressure is smaller. It can decrease the waste and make the service life longer.

● Print many kinds of material include various thin film reels.

● Adopt High precision cylinders, guiding rollers and high quality Ceramic Anilox roller to increase the printing effect.

● Adopt imported electric appliances to make the electric circuit control stability and safety.

● Machine Frame: 75MM thick iron plate. No vibration at high speed and have a long service life.

● Double Side 6+0; 5+1; 4+2; 3+3

● Automatic tension, edge, and web guide control

● We can also customize the machine according to customer requirements

Details Dispaly

Options

Check the printing quality on the video screen.

prevent fading after printing.

With two way cycle ink pump, no spill the ink, even the ink, save the ink.

Printing two roller at the same time.

sample

Packaging and Delivery

FAQ

Q: Are you a factory or trading company?

A: We are a factory, the real manufacturer not trader.

Q: How to get machines price?

A: Pls provide following information:

1)The color number of printing machine;

2)Material width and effective print width;

3)What material to print;

4)The photo of printing sample.

Q: What is a stack flexographic printing machine?

A: A stack flexographic printing machine is a type of flexographic printing press that features a vertical stack of print units. This design allows for increased printing flexibility and improved registration accuracy.

Q: What is the output speed of a stack flexographic printing machine?

A: The output speed of a stack flexographic printing machine depends on various factors, such as the number of print colors and the substrate being used.

6. Does a stack flexographic printing machine require any special maintenance?

A: Like any other printing press, a stack flexographic printing machine requires regular maintenance to ensure optimal performance and longevity. Routine cleaning, lubrication, and inspection of the machine parts are essential to prevent breakdowns and minimize downtime.