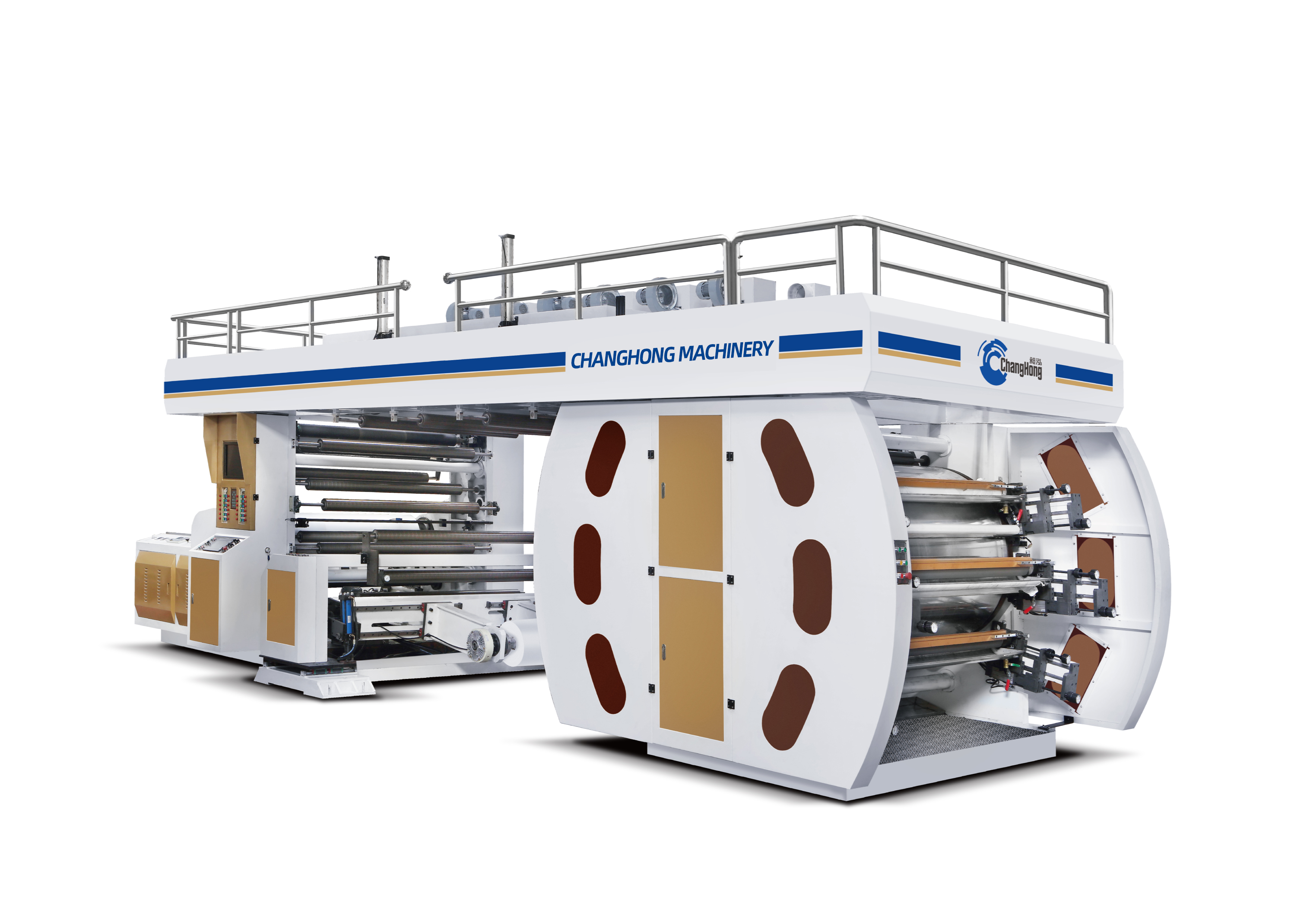

2025 Latest Design China Manufactured Good Quality 4 Colour Flexographic Printer for PP-Woven

With state-of-the-art technologies and facilities, strict high-quality management, reasonable price tag, top-quality service and close co-operation with clients, we’re devoted to delivering the top value for our consumers for 2025 Latest Design China Manufactured Good Quality 4 Colour Flexographic Printer for PP-Woven, Make sure you sense absolutely absolutely free to speak to us for organization. nd we believe we are going to share the ideal trading practical experience with all our merchants.

With state-of-the-art technologies and facilities, strict high-quality management, reasonable price tag, top-quality service and close co-operation with clients, we’re devoted to delivering the top value for our consumers for Flexographic Printer and PP-Woven Flexographic Printer, Our company has already had a lot of top factories and professional technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers’ satisfaction is our future!

technical specifications

|

Model |

CH4-600B-S |

CH4-800B-S |

CH4-1000B-S |

CH4-1200B-S |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

560mm |

760mm |

960mm |

1160mm |

|

Max. Machine Speed |

120m/min |

|||

|

Max. Printing Speed |

100m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ600mm |

|||

|

Drive Type |

Synchronous belt drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

300mm-1300mm |

|||

|

Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

Video Introduction

Machine Features

1. High production capacity: The three-unwinder, three-rewinder stacked flexo press has a fast printing speed and high output, allowing large quantities of labels and packaging to be produced in a short time.

2. Registration accuracy: The registration system of this press is highly accurate, ensuring superior print quality and perfect alignment of designs.

3. Flexibility: The three-unwinder, three-rewinder stacked flexo press can handle a wide variety of substrates, such as paper, cardboard, plastic film, and other materials, making it perfect for printing different products.

4. Easy operation: The machinery features a simple and intuitive control system, making it easy to use and reducing human error.

5. Low maintenance: The stacked flexo press with three unwinders and three rewinders has a robust and high-quality design that requires little maintenance and has a long service life.

Details Dispaly

sample

With state-of-the-art technologies and facilities, strict high-quality management, reasonable price tag, top-quality service and close co-operation with clients, we’re devoted to delivering the top value for our consumers for 2025 Latest Design China Manufactured Good Quality 4 Colour Flexographic Printer for PP-Woven, Make sure you sense absolutely absolutely free to speak to us for organization. nd we believe we are going to share the ideal trading practical experience with all our merchants.

2025 Latest Design Flexographic Printer and PP-Woven Flexographic Printer, Our company has already had a lot of top factories and professional technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers’ satisfaction is our future!