2022 Good Quality Full Servo Gearless Flexo Printing Machine - 8 colour CI printing machine – Changhong

2022 Good Quality Full Servo Gearless Flexo Printing Machine - 8 colour CI printing machine – Changhong Detail:

Characteristic

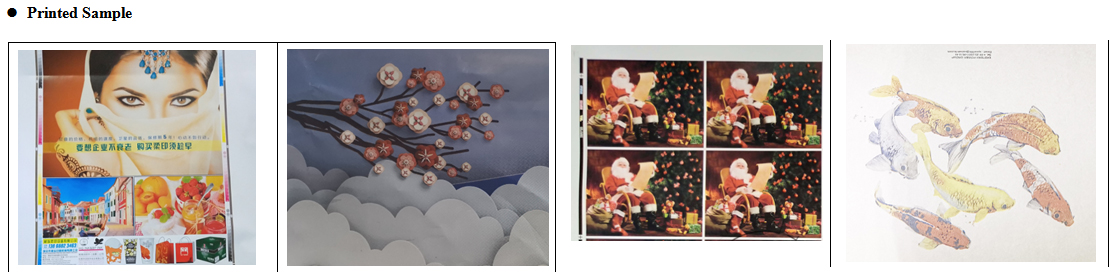

- The machine introduction & absorption of European technology / process manufacturing, supporting / full functional.

- After mounting the plate and registration, no longer need registration, improve yield.

- Replacing 1 set of Plate Roller (unloaded old roller, installed six new roller after tightening), only 20 Minute registration can be done by printing.

- The machine first mount plate, pre-trapping function, to be completed in advance prepress trapping in the shortest possible time.

- Maximum production machine speed up 200m/min, registration accuracy ±0.10mm.

- The overlay accuracy does not change during lifting running speed up or down.

- When machine stop, Tension can be maintained, the substrate is not deviation shift.

- The whole production line from the reel to put the finished product to achieve non-stop continuous production, maximize product yield.

- With precision structural, easy operation, easy maintenance, high degree of automation and so on, only one person can operate.

technical specifications

| Model | CHCI8-600S | CHCI8-800S | CHCI8-1000S | CHCI8-1200S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 300m/min | |||

| Printing Speed | 250m/min | |||

| Max. Unwind/Rewind Dia. | φ1200mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | 50-400g/m2 Paper. Non woven Etc. | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

MACHINE COMPOSITION

- unwind unit 1 set

- Satellite type printing unit 1 set

- dryer between each color 7 sets

- Drying box after printing 1 set

- rewind unit 1 set

- Auto EPC 2 set

- Video inspection 1 set

- Electric control system 1 set

- Ink circulation system 8 sets

- Central impression roller

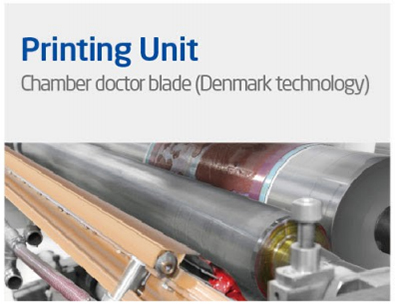

- Chamber doctor blade (imported Danish technology) 8 sets

Unwinding Unit

- Hydraulic shaftless Unwinding, the hydraulic arm can automatically rise and fall.

- The left and right movement adopts the fixed method of hydraulic central axis.

- Air-cooled magnetic powder brake control, with a range of about 20KG bilateral magnetic powder brake.

- Drive mode: Gear Drive

- Motor: Servo motor drive, inverter control closed loop control

Central Drum:

- double-layer structure steel processed by multiple heat treatment and shaping process

- Radial runout tolerance range is +/-0.010mm.

- The surface plating layer reaches more than 200um

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for 2022 Good Quality Full Servo Gearless Flexo Printing Machine - 8 colour CI printing machine – Changhong , The product will supply to all over the world, such as: Hamburg, Boston, Somalia, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

Write your message here and send it to us