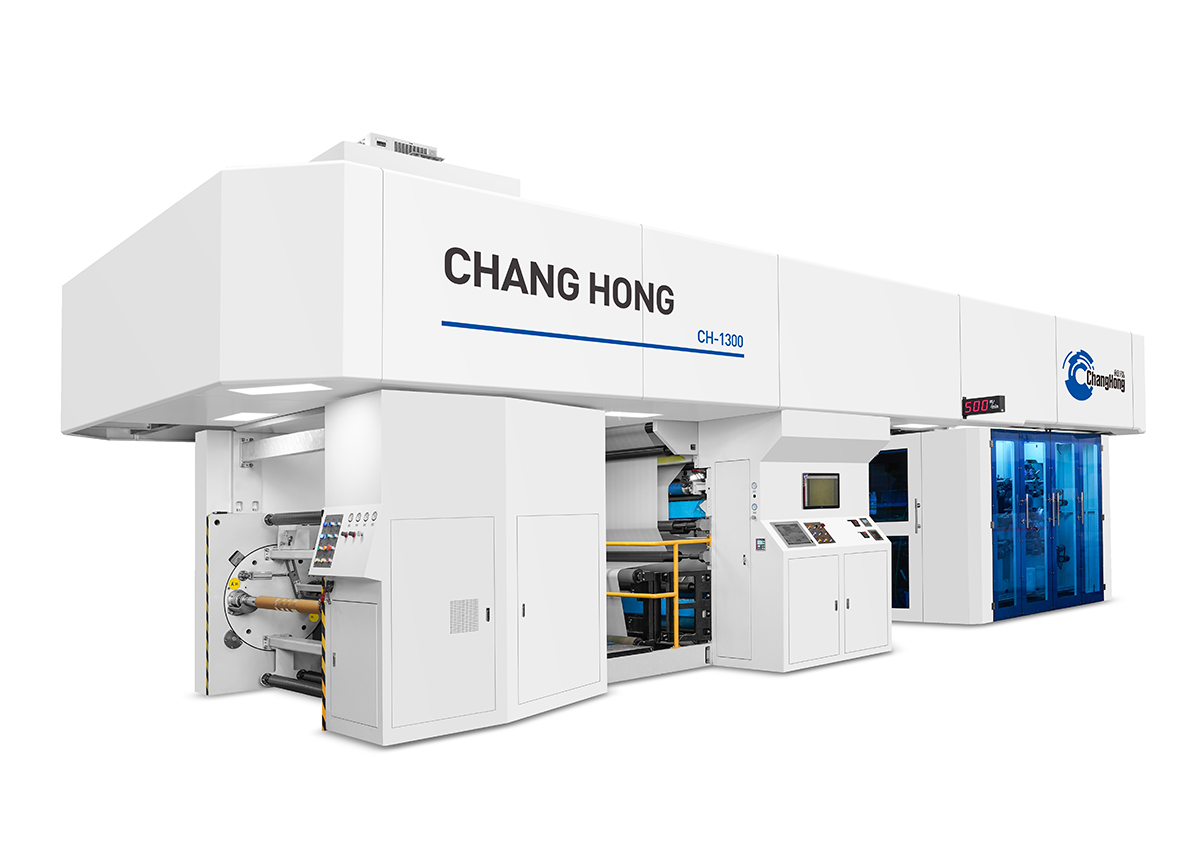

6+6 Color CI Flexo machine For PP Woven Bag

technical specifications

| Model | CHCI-600T | CHCI-800T | CHCI-1000T | CHCI-1200T |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 500mm | 700mm | 900mm | 1100mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ1500mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 500mm-1100mm | |||

| Printing way | 3+3.3+2.3+1.3+0.Full width.Both side | |||

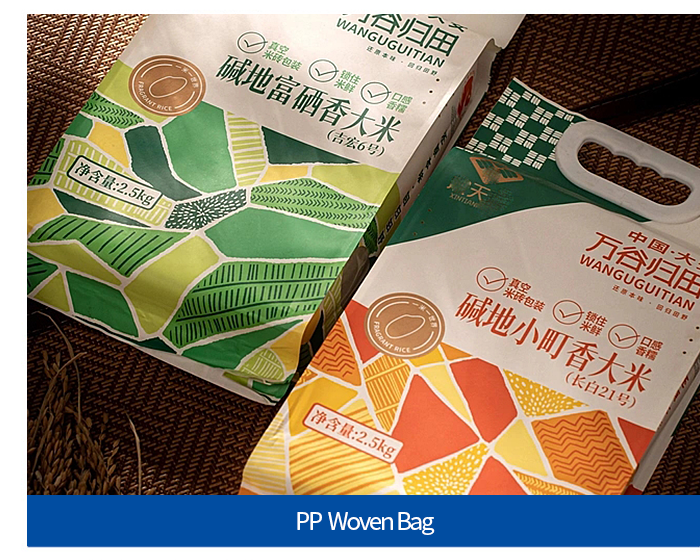

| Range Of Substrates | PP Woven Bags, Paper-Plastic Bags, Valve Bags | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video introduction

Characteristic

- The machine introduction & absorption of European technology / process manufacturing, supporting / full functional.

- After mounting the plate and registration, no longer need registration, improve yield.

- The machine first mount plate, pre-trapping function, to be completed in advance prepress trapping in the shortest possible time.

- The machine is equipped with blower and heater, and the heater employed central temperature control system.

- When machine stop, Tension can be maintained, the substrate is not deviation shift.

- The individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

- With precision structural, easy operation, easy maintenance, high degree of automation and so on, only one person can operate.

Details Dispaly

Printing Samples

Write your message here and send it to us